A zirconia milling machine is a tool used to shape and cut zirconia material for different purposes. This machine can handle tough and durable zirconia to make it applicable for crowns and bridges. However, dentists face some hurdles when operating this machine. The generation of a lot of heat and the cracking of the material are the common challenges. The machine works at high speed and pressure, which sometimes causes material breakdown. So, it’s essential for dentists to fully understand the working principle of this dental milling machine. In this article, we write a short guide on the zirconia milling machine, its types, and its practical applications.

Keep reading to explore what a zirconia milling machine is!

How Do Zirconia Milling Machines Work?

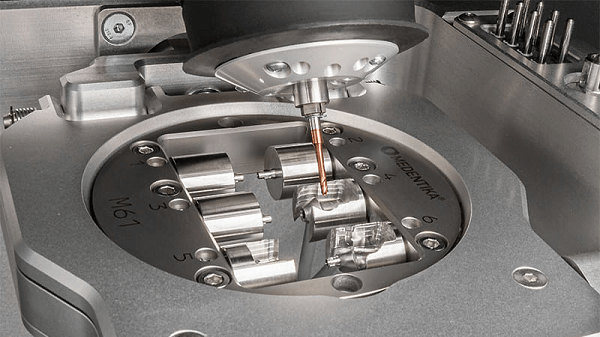

CAD CAM milling machines are equipped with a rotating tool inside the machine. The basic role of this tool is to carve zirconia blocks into specific shapes. First of all, a dentist places a block of zirconia material into the machine.

The machine has a computer-controlled system. This system guides the cutting tool to shape the zirconia block. The tool spins quickly and moves in different directions. This movement cuts the material into the required angle that enables you to easily mold or adjust. You can control the speed and pressure of the milling machine for zirconia to prevent the material from breaking.

What are the Types of Zirconia Milling Machines?

Generally, there are three different types of zirconia milling machines used in dental labs. Let’s explore the details of each type with pros and cons.

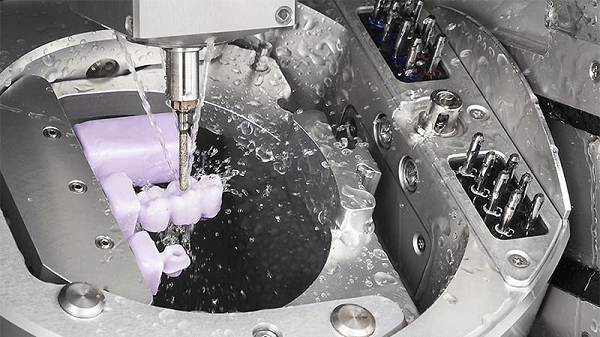

– Wet Milling Machines

This type of machine uses water or coolant during the milling process. It helps to keep the zirconia cool while it is being cut. The water reduces the heat produced during the milling process, which prevents damage to the material. Wet milling machines also produce less dust, making the workspace cleaner. You can create a smooth surface of zirconia without any extra work.

Pros:

- This machine reduces heat buildup.

- You can produce smooth, high-quality finishes.

- This machine keeps your workspace cleaner by reducing dust.

- This machine has the capability to work well with tough materials, like zirconia.

Cons:

- This machine requires extra maintenance to manage water or coolant.

– Dry Milling Machines

On the other hand, this dental milling machine does not use water or a coolant during the milling process. They depend on air to keep the milling tools cool. These machines are faster than wet milling machines. You do not need to use or dispose of coolant. Dry milling is also more energy-efficient since there is no need to run water through the system.

Pros:

- This machine is faster and more energy-efficient.

- You don’t need to manage water or coolant.

- The machine has a lower maintenance cost.

- Suitable for quick jobs and standard dental restorations.

Cons:

- This machine can generate more heat during material adjustment.

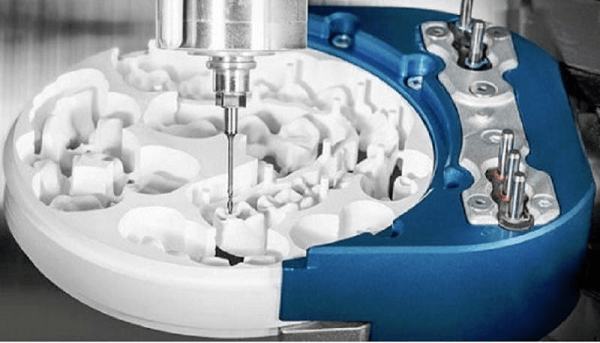

– Hybrid Milling Machines

Hybrid milling machines combine the features of both wet and dry milling machines. They give users the option to switch between wet or dry milling. The operation of this machine depends on the material and the job requirements. This flexibility enables dental labs to work with different materials like zirconia, wax, and PMMA.

Pros:

- This machine provides both wet and dry milling options.

- The machine provides flexibility to work with different materials.

- You can handle more complex jobs.

- It reduces the need for multiple machines in the lab.

Cons:

- This machine requires more training to use both wet and dry modes accurately.

Specifications of Zirconia Milling Machines

Zirconia milling machines possess exceptional key features that make them a worthy investment for dental labs. Let’s explore the main specifications of this machine.

1) Speed and Efficiency

This machine is known for its speed and work efficiency. You can mill a zirconia block into a dental restoration within just a few minutes. In a busy dental lab, faster machines help meet tight deadlines, making the process smoother. Efficiency, on the other hand, measures how well the machine uses time and resources. This machine can handle jobs quickly without compromising precision.

2) Precision and Accuracy

Precision and accuracy are the top key features of the zirconia milling machine. This machine can cut the material with high precision. It ensures the dental restoration fits better into the patient’s mouth. You can maintain a high standard for both functionality and appearance.

3) Size and Capacity

Dentists use this material due to its capacity to handle bigger Zirconia Blocks. This machine is available in small and large sizes. In a small-sized machine, you can mill one piece at a time and easily set it up in small offices. If you run a busy lab with lots of orders, a machine with higher capacity might be worth the investment.

4) Maintenance and Durability

Due to strong, robust construction, this machine is built to last. This machine requires fewer repairs. You can use this machine continuously to produce high-quality results. With regular cleaning and calibration, you can keep the machine in top shape. This is a cost-effective solution for dentists to make their investment worthy.

Top 3 Suppliers of Zirconia Milling Machines

Here are the details of the top three well-known brands in the market that provide quality machines.

– Aidite

Aidite is a well-established brand that focuses on innovation, precision, and accuracy. The brand mainly provides different dental appliances at an affordable range. Their team designs appliances built to last and require low maintenance costs. They provide wet, dry, and metal zirconia milling machines that can handle different types and sizes of zirconia. Their milling machines for zirconia are easy to use. It’s a user-friendly interface, and advanced features help users achieve great results quickly. It also has automatic tool-changing capabilities, which helps improve productivity.

– Roland DG

Roland DG is another top supplier of zirconia milling machines. They have a long history of producing high-quality machines. Their machines are designed to meet the needs of dental professionals who need reliability. Their machines are perfect for creating crowns, bridges, and other dental restorations. You can achieve excellent dental models with this machine. It also has an automatic tool changer that helps reduce downtime and improve productivity.

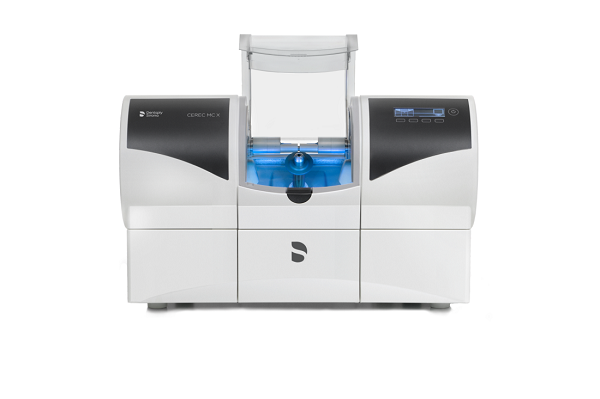

– Sirona

Sirona is also a popular supplier of zirconia milling machines. Their machines are highly considered for their accuracy and performance. Dental professionals use this machine due to its reliability and precision. The machine can handle a wide range of materials, including zirconia. Its powerful motor speeds up the milling process. It also has an integrated cooling system that prevents the machine from overheating. They also provide great customer support and training that facilitates the dentist using the new machine easily.

FAQS

What is the cost of a zirconia milling machine?

The cost of a zirconia milling machine depends on several factors. Generally, the average price of a milling machine is between $60,000 and $100,000. However, the types and sizes of the machines and the manufacturer’s reputation influence the overall cost.

What is the advantage of a milling machine?

The milling machines are famous for their precision and speed. This machine can mill the material with great accuracy. You can cut the material and minimize the material waste. This machine requires low maintenance and is built to last.

What is the working principle of a milling machine?

The working principle of a dental milling machine involves rotating a cutting tool to remove material. It speedily moves the material with great accuracy. You can make different sizes and shapes of dental restorations like veneers and bridges.

Final Thoughts

To sum up, a zirconia milling machine is an essential tool for dental labs that focus on creating quality restorations. This machine provides accuracy, speed, and reliability. With the integration of advanced technology, you can enhance overall productivity. However, it’s important for you to choose the right zirconia milling machine. You should keep a few factors like cost, speed, accuracy, and precision in mind. Make sure the machine meets the health care standards and is safe to use. Aidite provides an affordable zirconia milling machine price that requires low maintenance. So, choose wisely to improve your work quality.