Zirconia crowns have gained a lot of popularity due to their strength and natural appearance. However, patients and dentists both have one issue with zirconia crowns and that is the crowns coming off. The reason behind this is cementation. The choice of zirconia crown cementation material greatly impacts their durability.

Whether you are a patient or a dental practitioner wanting to know about zirconia cementation, this guide will walk you through all the necessary information. You’ll get to know about commonly used materials, zirconia crown cementation steps, and useful tips to achieve successful results.

Commonly Used Zirconia Crown Cementation Materials

When securing zirconia crowns there are several options available. Each zirconia crown cementation material has a unique set of advantages that could make it the best fit for your case. Let’s take a look at some commonly used materials:

RMGI (Resin-Modified Glass Ionomer)

RMGI is usually referred to as the gold standard of zirconia crown cementation. It is a hybrid material that combines the pros of glass ionomer and resin-based cement.

Numerous dentists use RMGI for the cementation of zirconia crowns due to its consistent balance between ease of use and performance. It has sufficient working time and forms a secure bond without needing complicated pre-treatment procedures.

Advantages of RMGI

The advantages of using RMGI for your zirconia crown are:

- Strong bonding to tooth structure

- Releases fluoride, which prevents future decay

- Less sensitive to moisture than purely resin-based cement

- Good retention on zirconia surfaces

- Cleaner removal of excess material

- High flexural strength

GI (Glass Ionomer)

GI is a tried-and-test zirconia crown cementation material. It is a reliable material used for decades in dentistry. Glass ionomer does not require a lot of surface preparation. It is used for zirconia cementation due to its ability to form a strong and long-lasting bond. It has shown consistent results in different clinical situations.

Advantages of GI

Here are the advantages of zirconia crown cementation with gic:

- Low shrinkage

- Chemical bonding with tooth structure without the need for extra primers

- Long-term fluoride release

- Thermal expansion characteristics comparable to natural tooth structure

- Less technique-sensitive than some other options

- Economic choice for zirconia crowns

Zinc Phosphate

Zinc phosphate has been used for decades in dentistry and is a good zirconia crown cementation material in several cases. Nowadays there are different materials available but still, many dentists prefer zinc phosphate. It is especially used when working with longer-span bridges or where isolation can prove difficult.

Advantages of Zinc Phosphate

Zinc phosphate offers the following advantages:

- Extended track record of clinical success

- Extremely thin film thickness for accurate crown seating

- Simple to apply with predictable setting times

- High compressive strength

- Suitable when maximum retention is not critical

Zirconia Crown Cementation Steps

Following proper zirconia crown cementation steps are critical to ensuring your restoration lasts. Here’s an easy process you can expect:

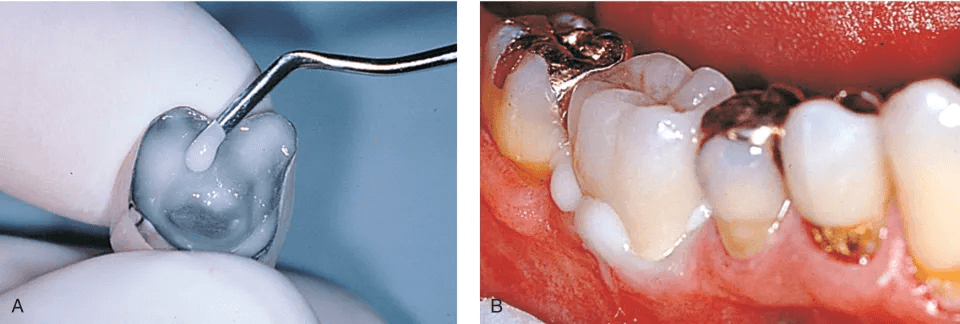

1. Try-in and Cleaning:

Your dentist will initially verify the fit of your zirconia crown. Once fit is confirmed, they’ll clean the crown and your tooth extensively. Cleaning the zirconia surface eliminates the contaminants that may compromise bonding.

2. Surface Preparation:

Depending on what the ideal cement for zirconia crowns is in your situation, the crown and tooth surfaces might require varying preparation. Zirconia, for instance, can be prepared with an air-abrasion method that provides microscopic roughness that enhances cement adhesion.

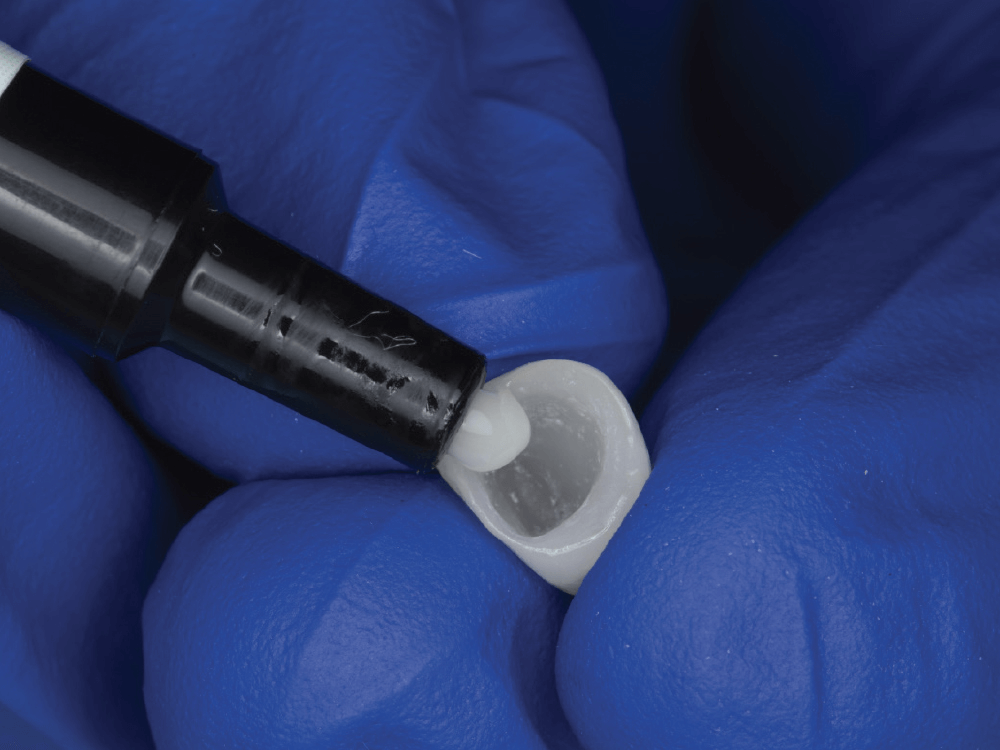

3. Application of Cement:

Your dentist will place the chosen cementation material on the inner surface of the crown. Even distribution is ensured to avoid gaps or pressure unevenness when seating the crown.

4. Seating the Crown:

The crown is seated on your prepared tooth carefully. Your dentist will ask you to bite down on a special paper to ensure that everything is in place.

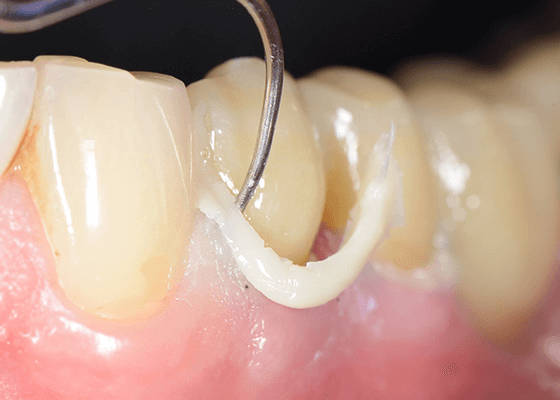

5. First Setting and Cleanup:

After it’s been positioned, excess cement is cleaned out while still soft. This process is important to avoid gum irritation and other issues later.

6. Final Curing and Final Adjustment:

Light curing can be employed to speed up setting based on the type of cement used. Final adjustments are made so that your bite feels normal with the new crown.

These zirconia crown cementation steps can differ slightly depending on your dentist’s technique of choice and the particular materials involved.

Tips for Zirconia Crown Cementation

For optimal success with your zirconia crown, keep these tips in mind:

- Avoid saliva contamination: For most types of cement, keeping the area dry is crucial. Utilize cotton rolls, rubber dams, or other methods to manage moisture.

- Follow Manufacturer Instructions: Every zirconia crown cementation material comes with particular mixing and handling instructions that greatly influence success rates.

- Select the right cement: Consider the patient’s needs before choosing the cement. The best cement for zirconia crowns usually relies on individual cases. Tooth location, crown thickness, and possible moisture control concerns all factors into this choice.

- Sufficient Preparation Time: It is best not to hurry when cementing a zirconia crown. Proper preparation of both the tooth and crown surface results in better bonding.

- Check Occlusion Thoroughly: Proper bite alignment after cementation ensures no complications arise in the future related to the crown cementation.

FAQ’s About Zirconia Crown Cementation Materials

Which material is used for zirconia crown cementation?

Some of the common zirconia crown cementation materials are resin-modified glass ionomer (RMGI) cement, glass ionomer (GI) cement, zinc phosphate cement, and resin-based cement. The selection of material depends on different factors including retention, bond strength, and case demands.

What is the best cement for zirconia crowns?

The best zirconia crown cementation material varies with the case. Resin-based cement provides the highest bond strength, while RMGI cement is best for fluoride-releasing and moisture-tolerant cases. GI cement can be used for mechanically retentive crowns.

How long will the zirconia crown last with proper cementation?

With proper cementation, zirconia crown may last 10–15 years or more. The longevity also depends on oral hygiene, the force of the bite, and the choice of cement. Regular checkup with the dentist ensures durability.

What is the best cement for zirconia crowns for the back of the mouth?

For posterior zirconia crowns, RMGI cement is usually favored for its excellent bond, fluoride release, and moisture resistance. Resin-based cements provide maximum adhesion for cases which have less retention.

Is zirconia crown cementation with GIC suitable for all cases?

Zirconia crown cementation with gic is ideal for those with good mechanical retention. Nevertheless, for short or unretentive preparations, resin-based cements are stronger and more stable in the long term.

Final Thoughts

Selecting the appropriate zirconia crown cementation material is crucial for the success of your zirconia crown. The cementation process is a meticulous, step-by-step procedure designed to achieve a strong bond between your natural tooth and the zirconia crown. Aidite’s advanced zirconia materials, such as the Superfect Zir and 3DPro Zir, offer excellent strength and natural aesthetics, enhancing the overall outcome of your restoration. With the high-quality materials and techniques available today, including those from Aidite, zirconia crowns can provide you with many years of functional and aesthetic satisfaction when expertly cemented by your dentist.