In conventional dentistry, dental restorations like crowns and bridges often require multiple patient visits and extended waiting periods. Dental milling machines have assumed great importance in modern dentistry because they enhance productivity and quality of service delivery periods. That is where dental milling machines come in to simplify the process of production.

Dental milling machines have become significant in the current dental practices as they improve both workflow and patient care. In this guide, we’ll explore the key features, different types, and top options available in the dental milling machine market.

What is a Dental Milling Machine?

A dental milling machine is a paradigm shift in the dental field as it enables the fabrication of accurate restorations such as crowns, bridges and veneers from ceramics, resins or alloys. It starts with a 3D scan of the patient’s mouth which guarantees the best fit and fast work.

So, what exactly does a dental milling machine do? These are computer-controlled tools that employ advanced CAD/CAM technology to shave accurate restorations from materials such as ceramics, for same-day treatment. Dentists can arrange their work in a more effective manner, and patients receive responses quickly.

Difference Types of Dental Milling Machines

1. Dry Dental Milling Machine

This dry dental milling machine is a specialized technology for specific dental restorations. These dental lab milling machines use pressurized air and a vacuum to remove material without water or coolant, like this gadget with five-axis linkage and 8 disc changers for continuous, automated production. Its intelligent fixture identification and C-shaped fixtures improve material utilization by 30%, enhancing efficiency and output.

Another prerequisite is its ability to work with moisture-sensitive materials like zirconium oxide. They are ideal for soft materials like zirconia, resin, PMMA, and wax but can also handle hard materials with small-diameter tools.

2. Wet Dental Milling Machine

Wet dental milling machines are essential in the processing of hard materials such as ceramics, metals and resins. They employ a liquid coolant to minimize frictional heat that may harm heat-sensitive parts such as glass ceramics and composite resins. It also cuts off unwanted material and gives a clean cut and a better finish to the material. This machine offers high precision and efficiency for personalized abutment and glass ceramic processing via its one-piece silicone safety door.

What does a dental milling machine do? It implants abutments, complete crown porcelain teeth, and simple prostheses, typically using four-axis mills. While materials like zirconia and titanium can be milled wet or dry, wax and acrylic materials require dry milling.

3. Combination Dry/Wet Dental Milling Machine

What is this dental milling machine about? A combination dry/wet dental milling machine offers flexibility by processing various materials in one machine. So, it is a one-stop solution for dental practices.

It can handle both sorts of milling, making it suitable for materials like zirconia, PMMA, wax, and composites. It guarantees accuracy and speed for numerous dental purposes such as reverse grip milling, harmonic drive, and water coolant.

A high-precision servo system and a tool magazine design with 25 slots to provide increased efficiency and higher accuracy for demanding implant applications.

Top 5 Dental Milling Machine Manufacturers on the Market

Every dental milling machine manufacturer incorporates unique features and operating systems into the machine system, so compatibility matters. Before considering any milling machine, focus on how its scanners align with your med lab’s needs. We’ve given some of the manufacturers’ top picks, pricing, and key specifications.

1. Aidite

The Aidite AMD-500E Dental Milling Machine is the ultimate solution for dental labs seeking precision, flexibility, and efficiency in one powerful package. This 5-axis dental milling machine is engineered for CAD/CAM processing of premium materials like zirconia, PMMA, and composite, making it an unbeatable choice for any lab.

Key Features & Benefits:

The Aidite AMD-500E offers several key benefits that make it stand out:

- 60,000 RPM Air-cooled spindle: Provides efficient and speedy milling and produces accurate and polished surfaces on even the most complex materials.

- Modular structure: It makes it easy to make changes and maintain, thus it can be made permanent and can be changed to suit new technologies.

- 90° vertical processing: Ensures that materials are used to the maximum and that wastage is discouraged due to high production standards.

- Automatic calibration and intelligent alerts: Convenience by guaranteeing that the process runs efficiently and does not need frequent or constant manual intervention or correction.

- Dust-proof design: Keeps the workspace clean, protects internal components, and extends the machine’s lifespan.

Priced at just USD 22,000, the Aidite AMD-500E offers value as one of the most cost-effective 5-axis dental milling machines today. So, experience the perfect balance of quality, performance, and affordability with Aidite—the best investment for all advanced labs.

2. Roland DG

The DWX-53DC dry dental milling machine by Roland DG is the next generation in dry dental milling technology. It is designed to work on different materials with high speed, precision and 24-hour productivity.

Key Features and Benefits:

- New spindle design for enhanced tool holding capacity with 3 x improved milling stability.

- The open-edge adapter enables advanced 90°+ milling for full-arch cases.

- Automatic disc changer offers 50% faster exchanges with up to six materials.

- User-replaceable spindle for easy, tool-free maintenance.

PS. This dental milling machine’s price is $43,995, or you can pay $880/month for a 60-month lease.

3. VHF

The VHF N4+, a premium dental milling machine manufacturer product, offers efficient wet grinding and milling for materials like zirconia, glass ceramics, and titanium abutments.

Key Features and Benefits:

- Compact design with a closed fluid circuit for efficient cooling.

- The automatic tool changer holds up to eight tools for quick changes.

- Precision confirmed by the University of Washington, with a range of −10 μm to +26 μm.

- Spindle with a maximum speed of up to 80000 rpm.

The N4+ is available at $31,750 and comes with industrial standards of performance and accuracy.

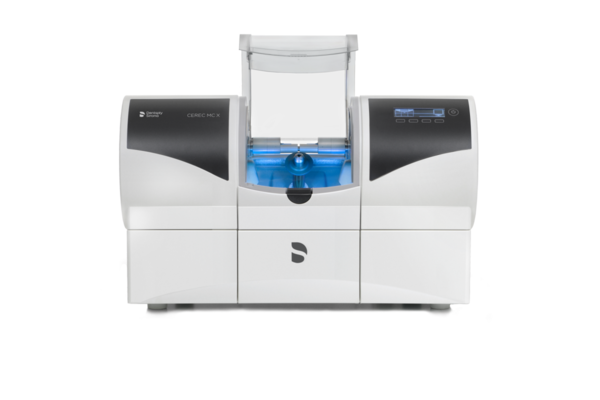

4. Dentsply Sirona

The CEREC MC X by Dentsply Sirona is one of the most popular dental milling machines that can be used in chairside mode thanks to high speed and precision. It produces inlays, crowns, veneers, and bridges with exceptional accuracy and smooth finishes.

Key Features and Benefits:

- Mills a crown in just 11 minutes, ensuring quick turnarounds.

- Handles blocks up to 55 mm, perfect for bridges and abutments.

- Compatible with cost-effective surgical guides for implant surgery.

Ideal for same-day restorations, this advanced machine is priced at $22,900 or $499/month.

5. Amann Girrbach

The Amann Girrbach Ceramill Mikro IC is a compact 4-axis dental milling machine offering wet grinding/milling for various materials, including titanium, composites, and glass ceramics. Its durable design ensures precision and efficiency.

Key Features and Benefits:

- DNA milling strategies for high-performance processing.

- Solid monocoque design offers stability and precision.

This compact machine, priced at $5300, combines versatility and speed, making it ideal for small labs.

Key Features to Look for in a Dental Milling Machine

When choosing a dental milling machine, consider these key features:

- Material Compatibility: Validate that the machine can handle a variety of materials like zirconia, metal, and ceramics for flexibility.

- Axis Range: A 5-axis machine offers higher precision and complexity than a 4-axis one.

- Automation and Software Integration: Advanced software improves control, accuracy, and ease of use.

- Speed and Efficiency: Faster milling times lead to improved productivity and shorter turnaround times.

These features directly impact your dental restorations’ quality, versatility, and efficiency.

FAQs about Dental Milling Machine

- What does a dental milling machine do?

A dental lab milling machine shapes restorations like crowns, bridges, and veneers from materials such as zirconia, ceramics, or metals. It uses precise CAD/CAM designs to carve detailed restorations, ensuring accuracy and efficiency. These machines are swift yet effective in creating high-quality and customized dental solutions.

- How much is a dental milling machine?

Are you curious about the cost of a dental milling machine? Depending on their features and brand, the price ranges from $5,000 for basic models to $50,000 for high-end machines.

- How to maintain a dental milling machine for longevity?

The only thing you need to look into regarding the maintenance of your dental metal milling machine is its cleanliness. Also, check the machine for tool wear and perform software updates and calibration. If you do it regularly, it’ll avert you from costly repairs and streamlining of operations.

- How do you choose between a wet and dry milling machine?

Choosing between a wet or dry milling machine depends on the materials you work with. Wet machines are ideal for ceramics, while dry machines work well with zirconia and resins. If you’re considering an Aidite machine, their models offer flexibility and advanced features for wet and dry milling, making them an excellent option for labs with diverse material needs. Hence, you must consider your lab’s needs, material types, and production volume before deciding.

Conclusion

Choosing one of the best dental lab milling machines depends on your lab’s material needs, production volume, and desired precision. Wet milling machines are perfect for ceramics, while dry machines excel with zirconia and resins.

Always consider the machine’s compatibility with different materials, automation features, and efficiency. Investing in reputable manufacturers like Aidite ensures you get high-quality, reliable machines with excellent customer support. This guarantees smoother operations and better results for your dental practice in the long run.