CAD/CAM milling burs are essential dental manufacturing equipment. They help in shaping and detailing materials like zirconia and ceramics to precise restorations. CAD/CAM milling burs allow crowns, bridges, inlays, onlays, and other dental restorations to be produced with high precision. Production of these dental restorations demands the high precision provided by these burs. This accuracy cannot be achieved manually. Aidite milling burs and other professional burs enhance dental CAD/CAM milling efficiency and accuracy which results in better outputs for dentists and patients.

Dental CAD/CAM Milling Burs

CAD/CAM technology has extensive applications in the dental industry, for the production of prosthetics. Dental CAD/CAM Milling Bur possess expert features like:

Specialized Characteristics

- Very high accuracy tolerances (usually ±0.01mm or higher),

- Made of biocompatible materials

- Designs optimized for specific dental materials.

Materials Typically Processed

- Lithium disilicate glass ceramics

- Zirconia (pre-sintered and fully sintered)

- PMMA for temporary restorations

- Composite resin blocks

- Wax for casting patterns

Advantages in Dental Uses

- Uniform quality in several restorations

- Precise marginal fit for better oral health

- Reduced chairside adjustment time

- Ability to mill challenging anatomical details

Types of Cad/Cam Milling Burs

There are different CAD/CAM milling burs for different requirements. The choice of the appropriate bur relies on the type of material one is milling and what result is sought. The selection of an appropriate type attains efficiency and precision in the procedure. The following are dental burs classified according to the material the burs are made of:

Tungsten Carbide Burs

Tungsten carbide burs are sturdy and sharp burs that can be used in cutting hard metals as well as metal alloys. They leave the surface with a smooth finish and are thus found in precision milling. The burs are highly utilized in clinics and laboratories owing to their endurance and efficiency.

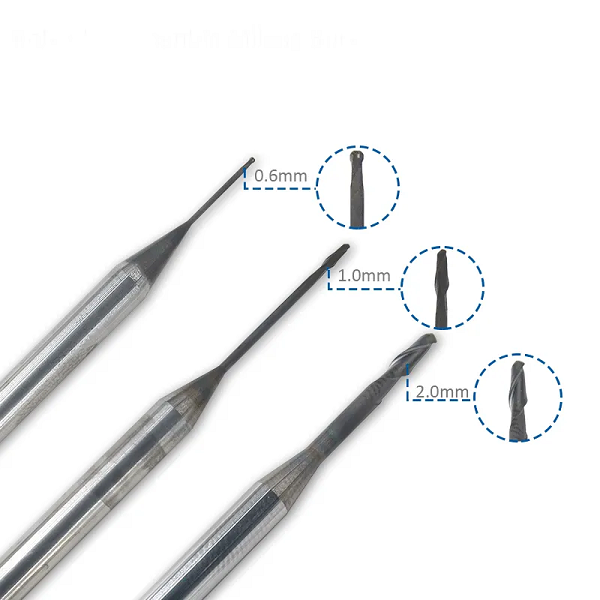

Diamond-Coated Burs

Diamond-coated burs are used in grinding and shaping hard materials such as ceramics and zirconia. Their diamond coating ensures precise cutting and contouring. They are utilized in milling ceramic crowns, veneers, and other restorations that demand extreme accuracy. The diamond coating offers more cutting efficiency, reducing milling time and improving efficiency.

Ceramic Burs

Ceramic burs are resistant to heat and perfect for use with thermoplastics and acrylics. They generate less heat while milling, reducing the risk of material damage. Ceramic burs are usually used where material integrity must be maintained, such as in the milling of temporary crowns and bridges. They are heat-resistant, making them an excellent choice for brittle materials.

Coated Milling Burs

Coated milling burs consist of special coatings such as titanium nitride which improves wear resistance and cutting efficiency. These coatings prolong the life of the bur and provide smoother cutting surfaces. Coated burs are generally employed for high-volume production in dental labs.

Applications of Dental Cad/Cam Miling Burs

CAD/CAM milling burs are employed in numerous dental treatments. The modern dental practice relies on CAD/CAM milling burs due to their accurate and efficient operations.

Restorative Dentistry

Dental CAD/CAM milling burs play a crucial role in restorative dentistry. They are used to mill crowns, bridges, inlays, and onlays. These restorations must be precise and have a good fit for patient comfort as well as functional purposes. Milling burs assist in attaining the precision that is required while reducing the need for adjustments. They also enhance the overall efficiency of the dental process.

Orthodontics

Orthodontists employ mill burs to produce clear aligners, retainers, and other orthodontic devices. These burs’ precision leads to results of treatment and accurate fitting of aligners. Orthodontic appliances become easier for patients to wear and more effective when precisely milled. They are hence a favorite tool in contemporary dental clinics.

Prosthodontics

Prosthodontics is the discipline of designing and fabricating dental prostheses, including dentures and implant-supported restorations. CAD/CAM milling burs ensure that these prostheses accurately fit and function effectively. Well-milled prosthetic components result in enhanced oral health and patient satisfaction via long-term and durable solutions.

Implantology

Dental implants require precise components to ensure successful placement and long-term stability. CAD/CAM milling burs help create custom abutments and implant-supported restorations with accurate dimensions. The use of high-quality milling burs enhances the success rate of implant procedures.

Aidite Dental Cad/Cam Milling Bur

Aidite is a well-known brand that manufactures high-quality CAD/CAM milling burs. Aidite milling burs are engineered for efficiency, lifespan, and accuracy.

Coating

Aidite offers diamond-coated milling burs which are best suited for zirconia milling, PMMA, and other materials. The diamond coating enhances the cutting effectiveness as well as the surface finish. Properly coated burs reduce wear and tear, promoting their life. Therefore, they are the best choice for dental labs requiring quality milling tools.

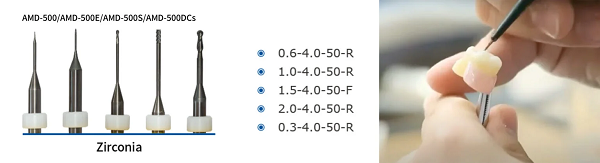

Compatibility

Aidite milling burs are interoperable with various milling machines, including AMD-500, Amann Girrbach, and VHF. Their compatibility allows dental practitioners to work with them in various CAD/CAM systems without experiencing any compatibility issues. This is the reason they are a favorite among dental professionals and labs looking for reliable milling tools.

Material

Aidite milling burs are made from German ultra-fine cemented carbide. This enhances their cutting precision and extends their lifespan. Quality materials ensure uniform performance and consistent results in dental milling. The high-quality construction of the burs guarantees sharpness even after multiple uses.

FAQs About Cad/Cam Milling Burs

How frequently should CAD/CAM milling burs be replaced?

You should inspect milling burs frequently for maximum performance. The lifespan of a bur also varies with the material being milled and the application. Dull burs can harm the milling machine. Thus, burs which are old have to be changed at once.

Can one bur be used for all materials?

No, don’t apply a single bur for every material. Various burs are for different materials. Using the proper bur for the material not only prevents ineffective cutting but also maximizes the use of the bur. For example, diamond burs are the ideal ones to apply on zirconia and metal alloys when the best type for them would be tungsten carbide.

How to maintain milling burs?

Proper cleaning and storage are required to preserve milling burs. Burs must be cleaned after each use to remove debris. Dry, organized storage prevents damage and extends shelf life. Proper maintenance extends the life of the burs and ensures uniform milling quality.

Are Aidite milling burs superior to others?

Aidite milling burs have a reputation for durability, precision, and compatibility with a wide range of milling systems. Their better construction and special coatings make them the dental lab’s first choice. However, the best bur to use for any purpose will depend on the material that is being milled as well as the final result desired.

Conclusion

CAD/CAM milling burs have a very significant position in contemporary dentistry. Dental clinicians apply them for precise fabrication of crowns, bridges, veneers, and other restorations. Choosing the right milling bur ensures accurate results and optimal workflow. Aidite milling burs and other high-quality burs help dental professionals produce the highest quality results for patients. Taking good care of milling burs is also extremely crucial to maximizing efficiency, accuracy, and longevity in dental milling processes.