As the field of dentistry continues to evolve, the need for high-quality, precise and efficient dental restorations has led to the widespread use of dental lab milling machines. These advanced devices use computer-aided design and manufacturing (CAD/CAM) technology to transform digital impressions into precise dental prostheses, such as crowns, bridges and dentures. I will take you through the details of the best dental lab milling machines to help you learn more.

What is Dental Lab Milling Machines

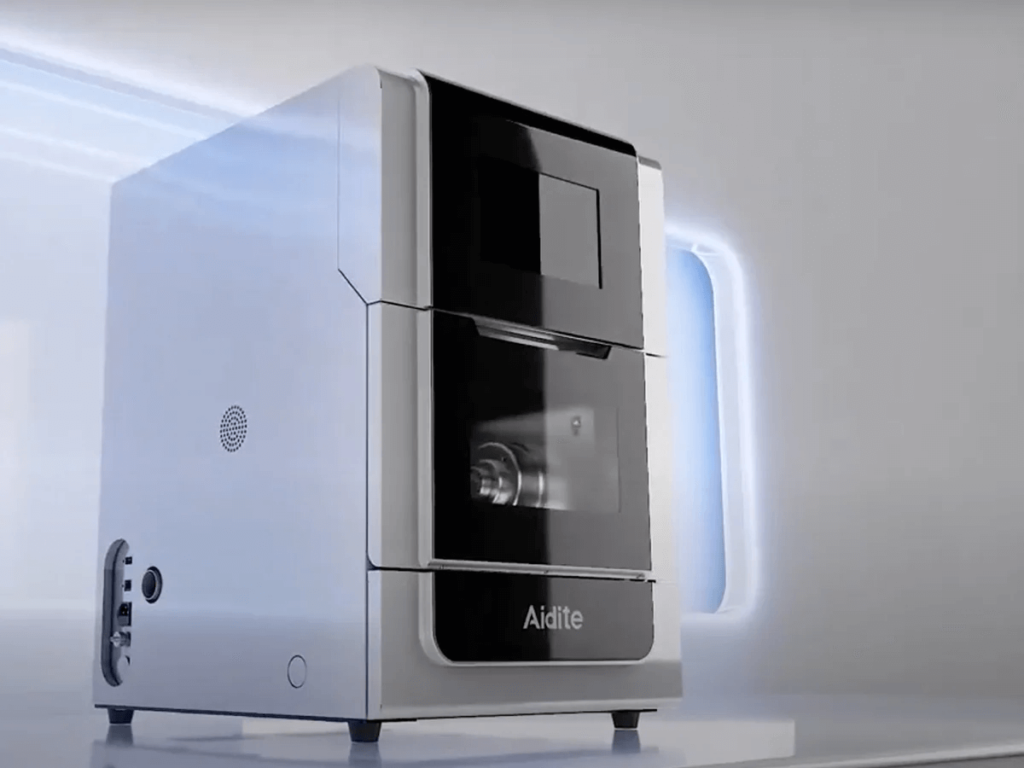

Dental lab milling machines are high precision equipment used in dental laboratories to create dental restorations such as crowns, bridges and inlets from materials such as zirconia, ceramic or resin. Aidite is a leading dental milling machine manufacturer that can enhance your dental practice and treatment outcomes with advanced milling technology.

Who Needs a Dental Lab Milling Machine?

Dental lab milling machines are very important for various dental professionals who focus on dental restorations. Here are the groups of people who need dental laboratory milling machines:

1. Dental laboratories

Dental laboratories that specialize in making dental restorations are the main consumers of restorative dental milling machines. Milling machines help them produce high-precision restorations more efficiently and reduce the time it takes to produce them.

2. General dentists

Creating in-house restorations for patients, which allows for shorter treatment times and better control of the quality of the restorations.

3. Restorative dentists

For tooth restorations and replacements, such as crowns or dentures, these machines enable them to create highly accurate and well-fitting prostheses, which are essential to the function and appearance of the patients’ teeth.

Types of Dental Lab Milling Machines

Sometimes you may wonder what types of dental lab milling machines there are. They are mainly classified based on the milling technology process and compatibility with the materials they are made of. Here is how it is classified:

1. Wet Milling Machines

- These dental lab milling machines use coolant during the milling process and are ideal for hard and brittle materials such as ceramics, composites, and more. Coolant helps dissipate heat, reducing the risk of material deformation and extending the life of the tool. However, they require a proper coolant handling system and may cost more to maintain.

- Applications: Highly aesthetic and high-precision crowns, veneers, and bridges

2.Dry Milling Machines

- Dry milling machines do not require the use of coolant and are suitable for materials such as zirconia and PMMA. It is generally easier to maintain and does not require coolant handling, making it more convenient to use.

- Applications: Full-arch restorations, temporary crowns, and models

3.Hybrid Milling Machines

- These versatile dental lab milling machines can help you do both wet and dry milling, with the flexibility to handle a variety of materials. They are particularly useful for labs that need multiple types of restorations.

- Drawbacks: the disadvantage is that they may require higher investment costs and maintenance costs, but the results are good.

Key Features to Consider When Selecting a Milling Machine

When choosing a dental lab milling machine, in addition to the basic functional requirements, you also need to pay special attention to the following important features. These features will affect the performance and user experience of your equipment.

1. Precision and accuracy

High precision is one of the most critical features of dental milling machines. Dental restorations, such as crowns, bridges or dentures, require extremely high precision to ensure that they can fit perfectly with the patient’s oral structure. Even a small error may cause the restoration to be unsuitable and need to be adjusted again, which affects the patient’s experience and comfort and increases the laboratory’s operating costs and time costs.

2. Material compatibility

The material compatibility requirements of the restoration materials for dental milling machines are very high, so it is very important to choose a milling machine that can handle commonly used materials in the laboratory.

Some advanced milling machines support the milling of multiple materials and can handle different types of materials from hard zirconium oxide to softer PMMA resins, which provides greater flexibility for dental laboratories. Especially for those laboratories that need to deal with diverse customer needs, it can greatly improve productivity.

3. Ease of use

Ease of use is critical for the selection of dental milling machines. In a busy laboratory environment, operators may not have complex mechanical operation skills at first, so they hope to have a simple machine that can be quickly used to reduce their own training costs and time.

4. Maintenance requirements

Dental milling machines are high-precision equipment. Long-term stable operation requires regular maintenance and strong technical support. Therefore, we must choose a supplier of milling machines that are easy to maintain and have reliable after-sales service.

Regular maintenance: such as tool replacement, cleaning, calibration and lubrication, so that the machine can maintain efficient working conditions for a long time. Simple and easy maintenance procedures and clear operating manuals are factors that many laboratories consider when choosing equipment.

Technical support and after-sales service: A good supplier usually provides continuous technical training and remote support to ensure that the equipment can be repaired at any time and reduce the inefficiency caused by equipment failure.

What are the Advantages of Using a Dental Lab Milling Machine?

- Improved productivity: Automated milling reduces labor costs and speeds up the production of restorations.

- Improved precision: Using digital high-tech design and manufacturing reduces errors and improves the compatibility and accuracy of restorations.

- Cost-effectiveness: The initial investment cost is higher, but in the long run, it reduces operating costs and material waste. The return on investment is slow and very substantial for you.

Choosing the Best Dental Lab Milling Machine – Aidite

Aidite is a leading supplier and manufacturer of dental materials and equipment, with advanced milling technology that can enhance your dental practice, ensuring accuracy, efficiency and excellent patient treatment results. Therefore, I recommend you to use Aidite’s dental lab milling machine, which is a model of high precision and high efficiency.

Recommended Milling Machine: CMD-500

The CMD-500 is a 5-axis dry milling machine optimized for chairside applications. With advanced CAD/CAM integration, durable cast aluminum design, and innovative features, it delivers efficient and precise results for Zirconia and PMMA.

Features:

- Precision: It uses advanced 5-axis technology to achieve complex and precise milling to cope with complex restorations.

- Indication: It has a wide range of applications and can handle various situations where dental lab milling machines are used, meeting all your dental surgery requirements.

- Software: It is compatible with mainstream CAM software, achieving seamless workflow and having a user-friendly interface, saving your labor and training costs.

- Ergonomics: Features a space-saving structure, ideal for chairside settings where space is limited. Features an ionized dust management design for cleaner operation and reduced maintenance.

If you are interested in dental milling machines, then know that Aidite can help you choose the best dental lab milling machine.

FAQ

1.How do I maintain a dental milling machine?

This is as simple as regular cleaning, checking cutter wear and ensuring machine components are functioning properly. Optimal performance is maintained through regular calibration and software updates.

2.What is the difference between a wet and dry dental milling machine?

There are differences between the two. One requires the use of coolant and the other does not. The wet type is more suitable for hard and brittle materials, while the dry type is suitable for materials such as zirconia and PMMA.

Conclusion

A dental lab milling machine is a high-precision device used to make dental restorations such as crowns, bridges and implants with materials such as zirconia, ceramics or resins. When choosing a dental milling machine, dental professionals usually consider various factors. If you want to choose the right dental milling machine, Aidite milling machine is an ideal choice for dental laboratories that pursue efficiency, precision and reliability. Choose an Aidite dental lab milling machine to help your dental practice move to a higher level.