Technology has revolutionized the dental field by introducing new ways of improving patient outcomes and creating dental restorations. 3D printing vs milling in dentistry are the most trending technologies used nowadays. Understanding the difference between 3D printing vs milling in dentistry is vital for dentists.

In the article below, we will compare 3D printing vs milling in dentistry, focusing on the advantages of 3D printing in dentistry and the advantages of milling in dentistry. You can clearly understand both technologies and select the most suitable between 3D printing vs Milling in dentistry.

Let’s move forward and compare the advantages of 3D printing in dentistry with the advantages of milling in dentistry.

- What is 3D Printing in Dentistry:

- Advantages of 3D Printing in Dentistry:

- Disadvantages of 3D Printing in Dentistry:

- What is Milling?

- Advantages of Milling in Dentistry:

- Disadvantages of Milling in Dentistry:

- Key Consideration While Choosing Between 3D Printing Vs Milling in Dentistry:

- 3D Printing Vs Milling in Dentistry: Which Technology is Best for You?

- FAQs:

What is 3D Printing in Dentistry:

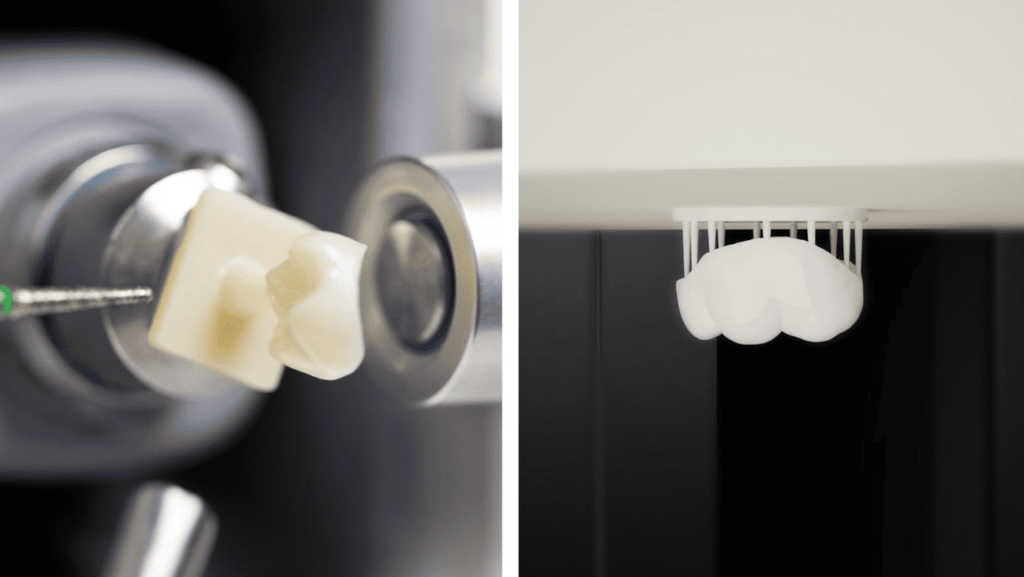

3D printing in dentistry is the process of using additive manufacturing technology for designing dental restorations, prosthetics, and models. This process starts with the creation of a digital design using CAD software and then crafting the restoration according to the design. A 3D printer is used with the help of CAM software which carefully processes the material like plastic, PMMA, Zirconia, and resin to craft the restoration. There are many advantages of 3D printing in dentistry you can avail and effectively enhance your patient satisfaction. The Aidite CPD-100 DLP 3D Printer offers high-precision 3D printing solutions for dental applications. It allows for accurate and efficient production of a wide range of dental restorations, enhancing both the quality and speed of dental treatments.

Advantages of 3D Printing in Dentistry:

3D printing in dentistry is famous for producing high-quality dental restorations with precision. It is often used for creating dentures, bridges, crowns, veneers, and orthodontic devices in the dental field. Some of the common advantages of 3D printing in dentistry are described below.

Precision and Customization:

One of the greatest advantages of 3D printing in dentistry is the ability to produce customized dental restorations that fit perfectly in a patient’s jaw. Using a 3D printer, you can craft detailed designs without any difficulty or human error.

Efficiency and Fast Speed:

3D printing in dentistry significantly reduces production time compared to other traditional methods. It enables dentists to work quickly and complete a project in just a few hours rather than days.

Cost-Saving Production:

The 3d printers can be expensive in terms of initial cost but offer lower production costs with minimal material waste. Another major factor for low production cost is its automatic processing, which eliminates labor needs.

Innovative Applications:

The creation of innovative restorations is another unique, one of the advantages of 3D printing in dentistry that may not be possible with other methods. For example, you can create personalized orthodontic aligners, surgical guides, and multipart dental restorations using 3D printing in dentistry. It is an upper edge when comparing 3D printing vs milling in dentistry.

Disadvantages of 3D Printing in Dentistry:

While you can get the above advantages of 3D printing in dentistry, there are fewer limitations that you need to understand. The common drawbacks are described below for your consideration.

High Initial Cost:

The high initial investment is a major disadvantage of 3D printing in dentistry. As 3d printers are the latest technology machines, they are best for high-quality and bulk production. This factor makes them unsuitable for small clinics and those with limited budgets.

Material Limitation:

Some printers rely on specific materials like metal, plastic, PMMA, and resins to create dental restorations. These materials sometimes don’t offer the durability and strength required for any dental implant, limiting their use only for products like bridges and crowns. This gives an edge to milling when comparing 3D printing vs milling in dentistry.

Sterilization:

The porosity and material characteristics of the dental restoration designed with 3D printing in dentistry make sterilization hard and challenging. Post-printing procedures are fundamental to sterilizing restorations before use. It needs extra time and enhances the overall cost of the treatment.

What is Milling?

The subtractive manufacturing process where a computerized machine mills a solid block of material to create a dental restoration is called milling. There are unlimited advantages of milling in dentistry, including processing ability for all types of materials. The milling machine works according to the digital design fed into the machine for automatic production. You can craft high-quality dental restorations by using a dental milling machine like Aidite AMM-580 Dental Milling Machine. Some common advantages of milling in dentistry are described below for your understanding.

Advantages of Milling in Dentistry:

The unlimited advantages of milling in dentistry still make it a preferred choice for dentists looking for durability and precision in their work.

Material Support:

The ability to process a wide range of materials including composite resins, PMMA, Zirconia, ceramics, and metal is one of the key advantages of milling in dentistry. You can create high-strength, and durable dental restorations like veneers, bridges, and crowns with a milling machine.

Strength and Durability:

When we compare 3D printing vs milling in dentistry, the milled dental restorations are typically more durable and stronger than the printed ones. The milling process tends to produce more resilient dental implants by the precise carving of a solid material block.

Reliability and Precision:

The streamlined functionality of milling machines enables the production of highly accurate and well-fitted dental restorations. It is still widely used in many dental procedures because of its consistency and process alignment.

Proven Track Record:

Another important, one of the advantages of milling in dentistry is its many years of use in the industry for the production of restorations. Its long track record and ability to craft durable dental restorations make it a preferred choice for many professionals.

Disadvantages of Milling in Dentistry:

There are numerous advantages of milling in dentistry and a few drawbacks that are described below for your consideration.

Long Production Time:

The milling takes more time to prepare a dental restoration when comparing 3D printing vs milling in dentistry. Its subtractive process of removing material layer by layer can take hours to complete the full restoration.

High Maintenance Cost:

The milling machines require trained operators to work on and also the parts and maintenance is expensive than the 3d printers.

Material Waste:

Milling wastes a lot of material, as the process involves layer-by-layer cutting of a solid material block to prepare the dental restoration. On the other hand, 3d printing in dentistry minimizes the excessive use and waste of material in the production process.

Key Consideration While Choosing Between 3D Printing Vs Milling in Dentistry:

Some of the key factors to consider while comparing 3D printing vs milling in dentistry are listed below. As a professional, you need to understand these and consider them while choosing equipment for your lab.

- Accuracy and precision

- Material support

- Processing speed

- Customized production and flexibility

- Durability and strength of the final product

- Your budget and initial cost with maintenance

- Operating and required skill

- Your patient needs

3D Printing Vs Milling in Dentistry: Which Technology is Best for You?

The selection depends on your needs and requirements when choosing between 3D printing vs milling in dentistry. Consider the following scenarios to determine when each method is most suitable:

Use 3D Printing When:

- Customization is Key: Ideal for complex or personalized restorations like aligners or surgical guides.

- Fast Turnaround is Needed: Perfect for quick production, such as same-day restorations or prototypes.

- Small Production Volumes: More cost-effective for low-volume, automated production with minimal waste.

Use Milling When:

- Durability and Strength Matter: Best for high-strength restorations like metal crowns or ceramic veneers.

- Large-Scale Production: Reliable for high-volume, consistent output.

- Precision and Longevity are Important: Ideal for restorations requiring long-term durability and precise finishes.

FAQs:

1. What is the key difference between 3D printing vs milling in dentistry?

The main difference between 3D printing vs milling in dentistry is that milling is carving from a solid block of material. While 3d printing in dentistry is building layers of material during the production of dental restoration.

2. What are the advantages of 3D printing in dentistry?

Fast turnaround time, high customization, low material waste, and innovative production of dental restorations are some of the common advantages of 3D printing in dentistry.

3. What are some advantages of milling in dentistry?

The common advantages of milling in dentistry are flexibility, material versatility, resilience, and durability.

Conclusion:

Choosing between 3D printing vs milling in dentistry just depends on your specific needs. You can grasp both technologies aptly by contrasting the advantages of 3D printing in dentistry and the advantages of milling in dentistry. If you want to go for a milling machine, the Aidite AMM-580 Dental Milling Machine is a top engineered and perfect choice for you.