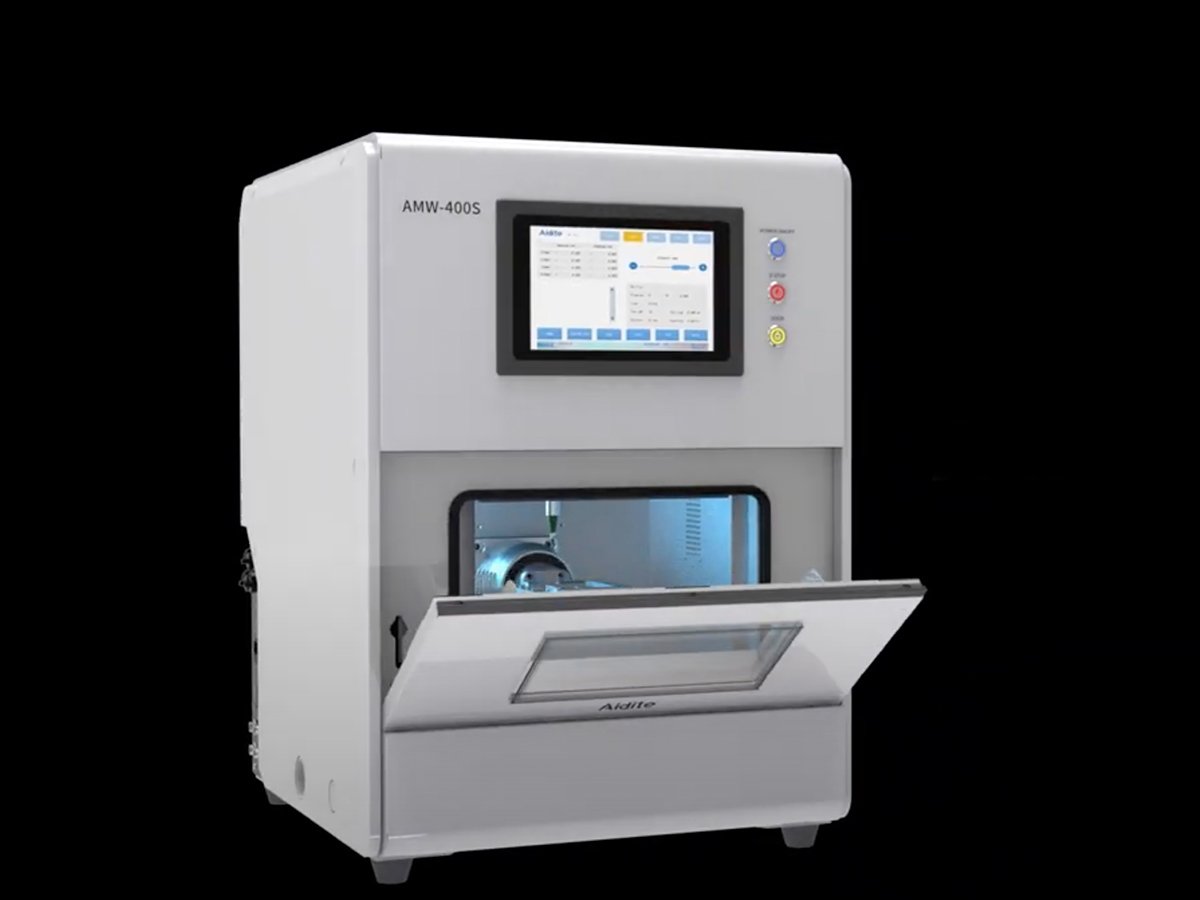

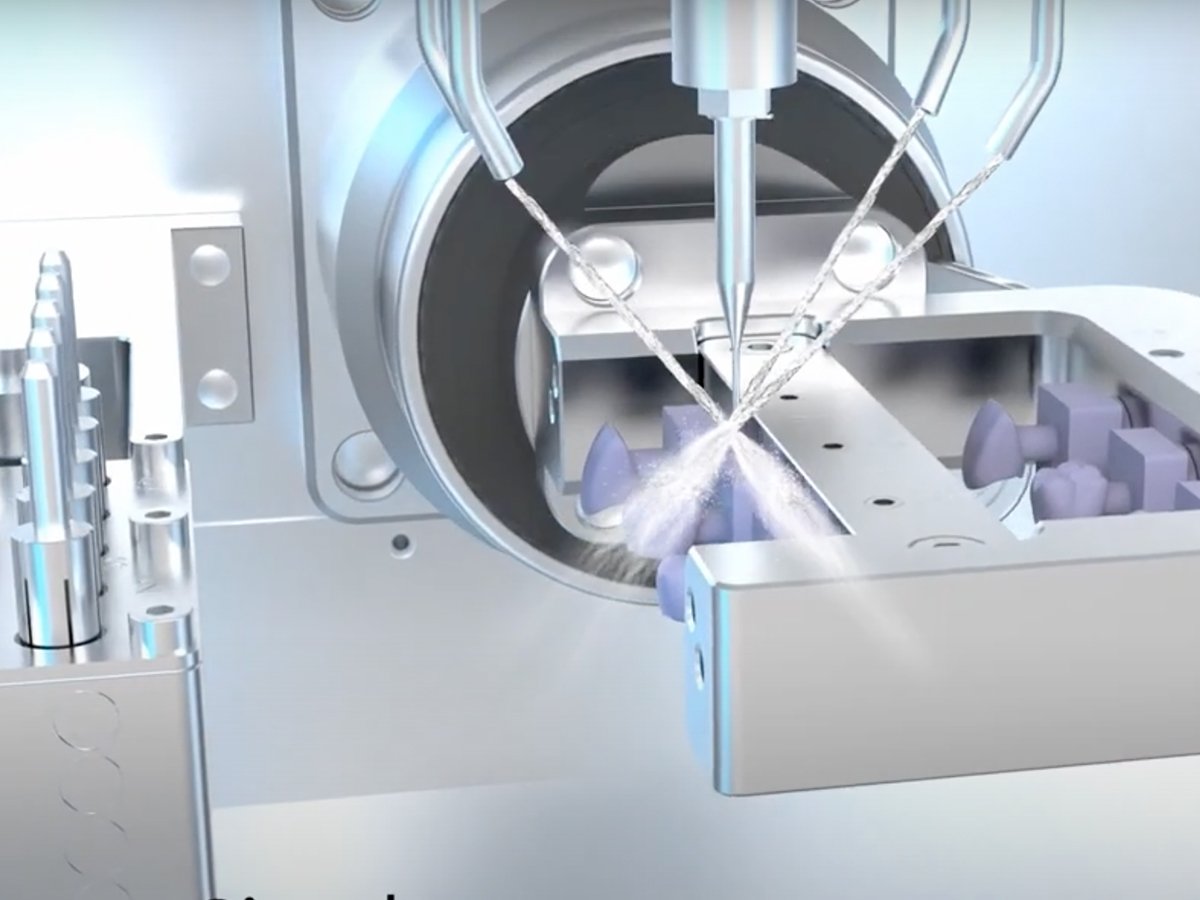

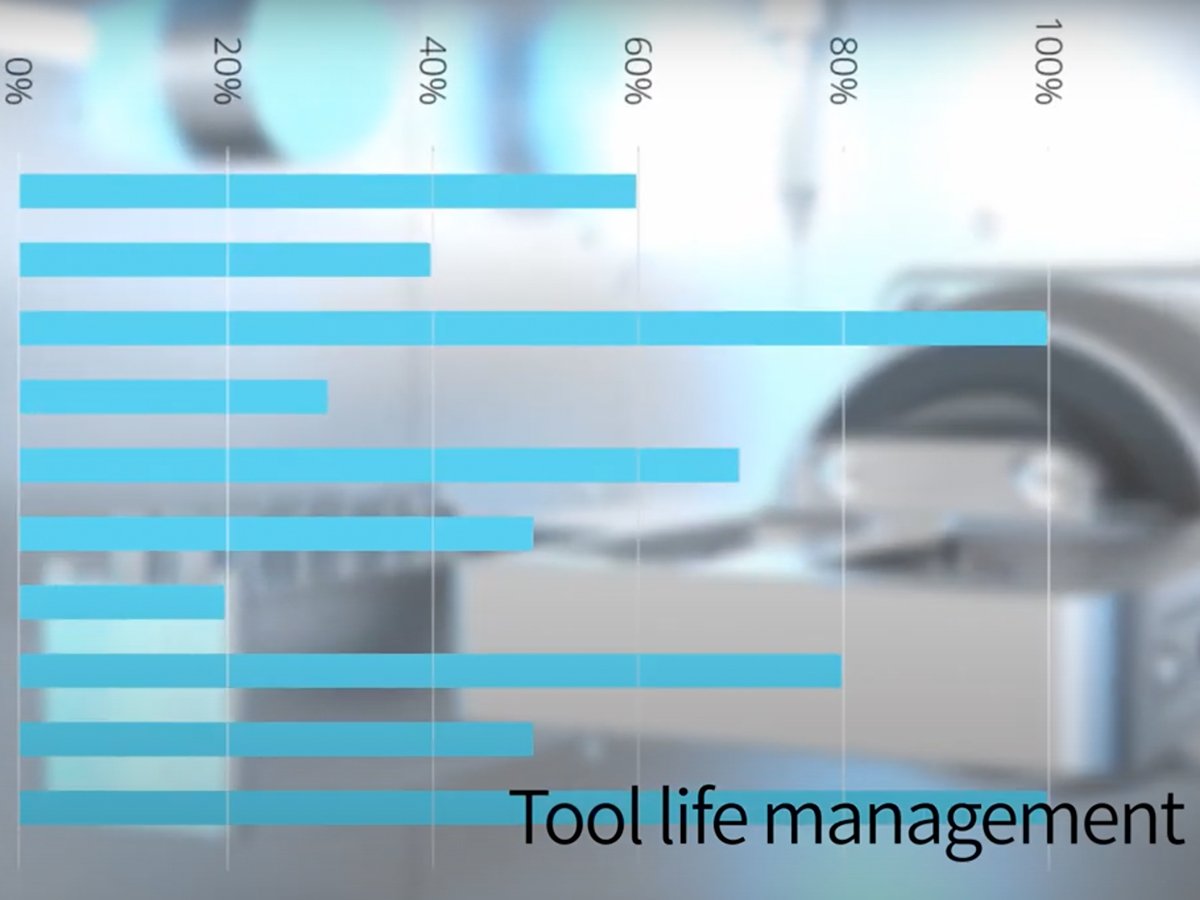

The AMD-400S is a reliable and high-performance dental milling machine created for dental labs and clinics. It is ideal for zirconia, glass ceramics, premills, and PMMA, offering precision and efficiency. With features like tool life management, silicone dustproofing, and a user-friendly interface, it’s the best choice for personalized abutments and dental restorations.