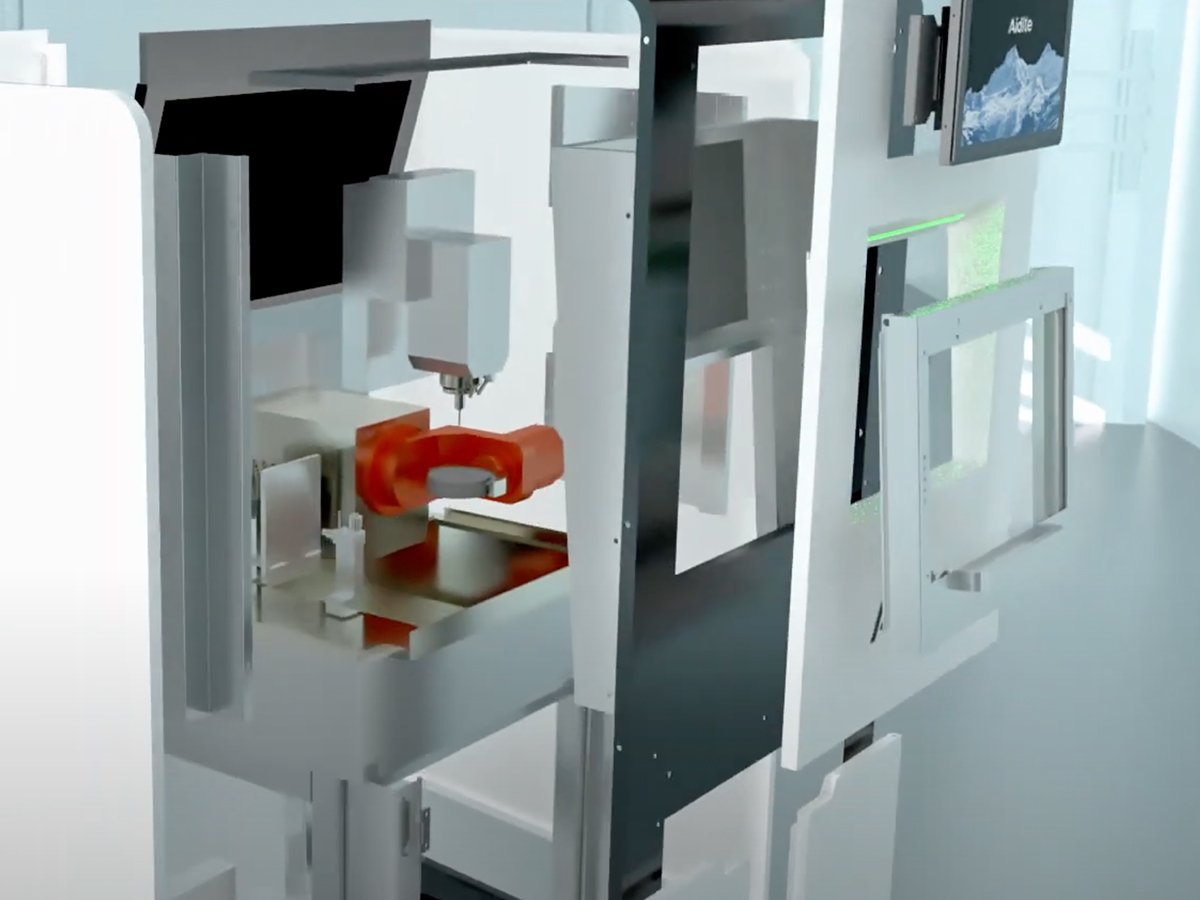

The Aidite AMD-500DCs is a leading dental milling machine made for high-end dental labs and clinics in China. It offers five-axis milling with 24/7 operation, an 8-disc changer, and intelligent fixture recognition. Perfect for making crowns, bridges, and veneers, it features a compact design and high-speed spindle technology. This dental milling machine is efficient, precise, and minimizes material waste, making it the best choice for dental clinics and labs.