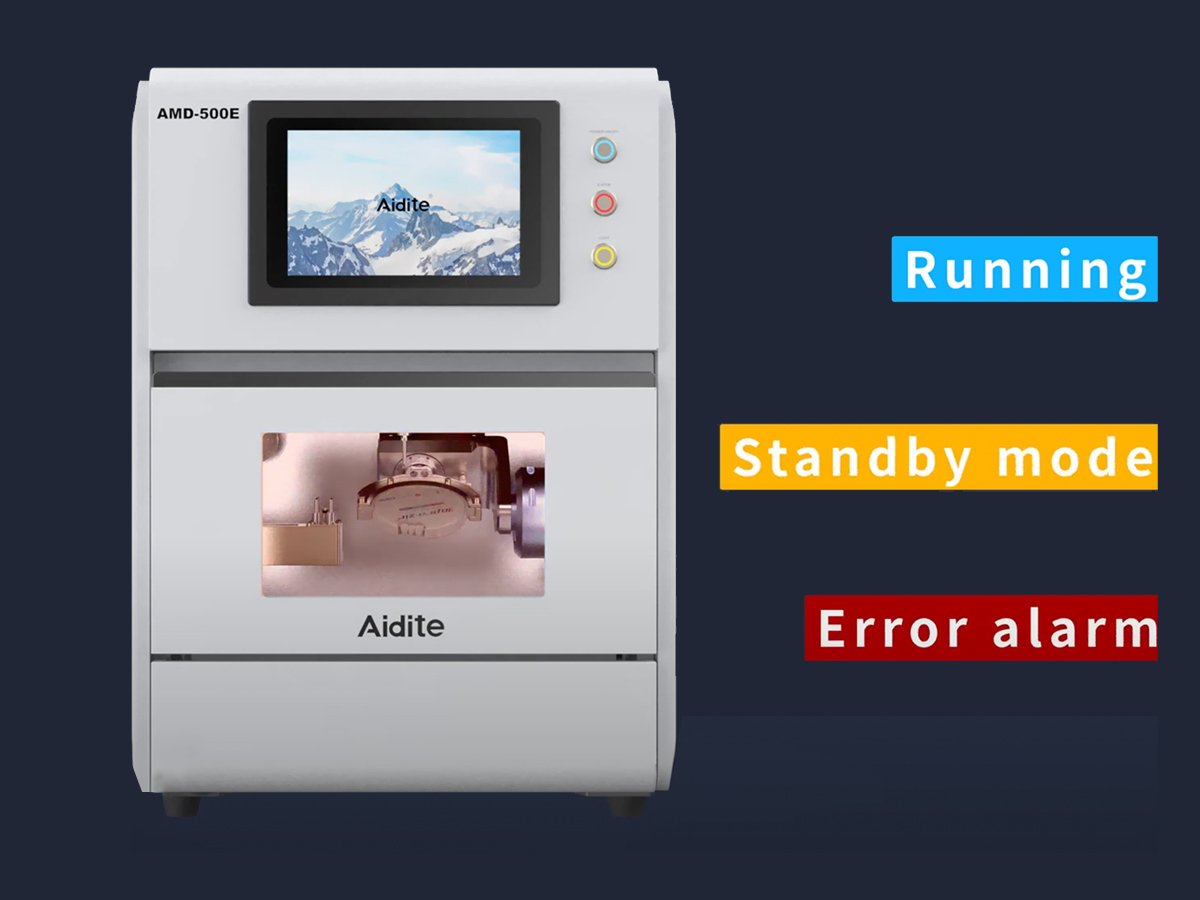

The AMD-500E is a high-performance 5-axis dry milling machine designed for precise CAD/CAM processing of various dental materials. Featuring a dust-proof design, 90° vertical processing, and intelligent tool management, it is ideal for producing crowns, bridges, veneers, and other restorations efficiently and accurately in modern dental laboratories. This dental milling machine is perfect for dental clinics and labs seeking reliable, cost-effective, and high-quality solutions for digital dentistry.