When dealing with CAD/CAM restorations, material selection is very important. What you select impacts everything from strength to aesthetics to longevity. With an increasing number of dental CAD/CAM materials, it becomes difficult to choose. With each material having different advantages, the question is no longer simply finding a material, but rather selecting the one that best fits your clinical situation.

In this article, we’ll analyze the main categories of dental CAD/CAM materials: ceramics, metals, polymers, and hybrids. Whether you’re in a laboratory, clinic, or somewhere in between, knowing these options will facilitate your long-term success.

What are Dental CAD/CAM Materials?

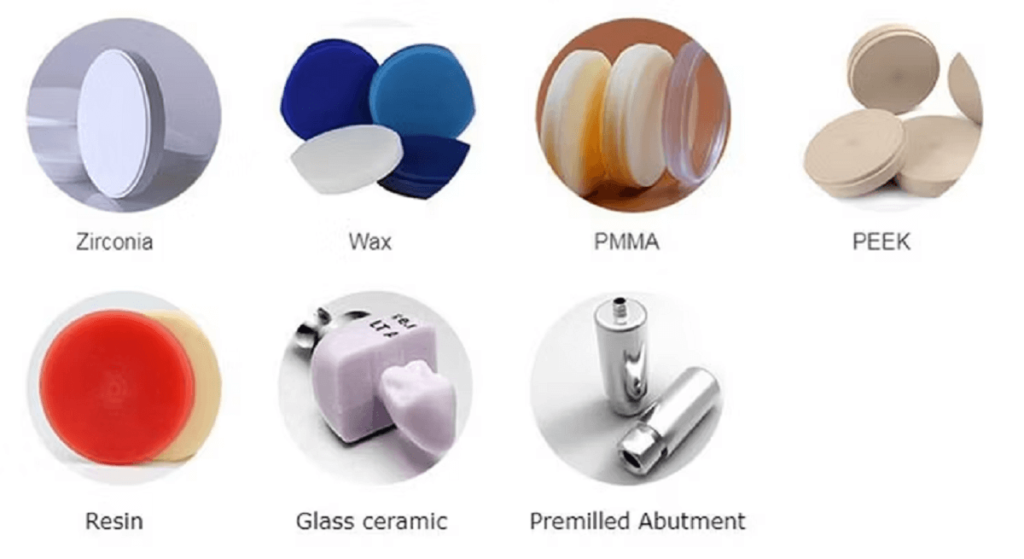

Dental CAD/CAM materials are prefinished blocks or discs that are used for fabricating crowns, bridges, inlays, dentures, and other restorations. These restorations are made using computer-aided design and computer-aided manufacturing systems. Dental CAD/CAM materials are chosen considering:

- Strength

- Aesthetics

- Processing ease

- Biocompatibility

Dental CAD CAM materials are also required to be compatible with digital workflows, providing precision and consistency when milled. Knowing these materials and their characteristics helps in simplifying the restoration procedures and obtaining predictable clinical results.

Ceramic CAD/CAM Materials

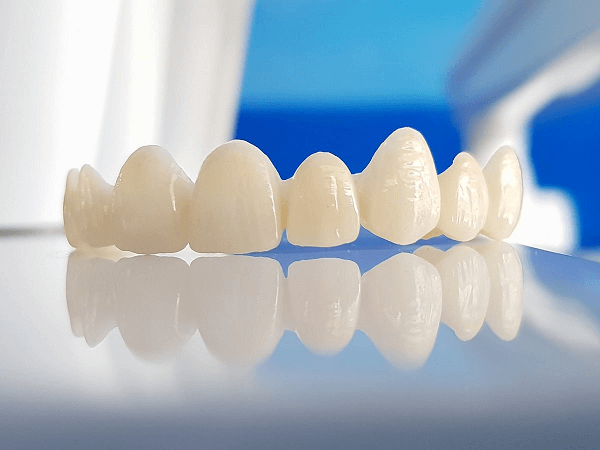

Dental CAD/CAM ceramics commonly include zirconia and lithium disilicate. Ceramics are resistant to wear, color-stable in the long term, and easily fit into the anterior and posterior regions of the mouth. When used in dental restorations, ceramics provide high detail and a natural appearance. Their biocompatibility and durability make them even more valuable. They are among the most trustworthy materials employed in restorative dentistry.

Zirconia

- Zirconia provides good flexural strength and toughness for long-span restorations

- Available in multilayered forms to deliver natural color gradients

- Performs well in crowns, bridges, and implant-retained prosthetics

- Supports rapid sintering to enhance workflow efficacy.

Lithium Dissilicate

- Lithium disilicate delivers improved translucency for aesthetic restorations

- Best used for anterior crowns, veneers, inlays, and onlays.

Metal CAD/CAM Materials

Metals are still used as dental CAD/CAM materials, especially for situations where strength and stability are required. They are crucial for implant restorations, removable partial dentures, and large-span bridges. Their durability and performance under mechanical stress cannot be beaten by other groups. Digital processes make the design and milling of these parts easier. They are the number one option for biocompatible and stress-resistant restorations. Although they do not look aesthetic but they offer unexcelled structural stability in functionally stressed areas.

Titanium

- Lightweight and biocompatible for custom frameworks and abutments

- Corrosion and mechanical stress resistance

- Long-term comfort and excellent tissue response

Cobalt-chromium (Co-Cr)

- High strength for bridges and partial denture bases

- Fit and function are retained over time under load

Polymer CAD/CAM Materials

Polymers are valuable CAD/CAM materials in dentistry because of their ease of milling and use in temporary restorations. Polymers are light, flexible, and budget-friendly. While they do not have the strength of ceramics or metals, they serve valuable roles in restorative workflows. They are also easy to reline or repair.

Polymer Resin

- Best suited for mock-ups, treatment planning, and temporary crowns

- Conveniently milled and polished for rapid turnaround

- Offers temporary functional and aesthetic direction

PMMA

- Commonly used in dentures and long-term temporaries

- Stable color retention along with a high-gloss finish

- Effective in full-arch and removable prosthetics

Hybrid Materials

Hybrid dental CAD blocks blend ceramic and resin components into one end-use material. These materials retain aesthetic qualities and also offer flexibility and enhanced stress distribution. They’re less brittle than complete ceramics and more robust than resins, bringing the middle ground between the two types.

Ceramic-resin Hybrids

- Provide flexibility with excellent wear resistance

- Quicker to mill and polish chairside

- Less abrasive on opposing teeth, minimizing attrition

- Suitable for inlays, onlays, and partial crowns

Dental CAD/CAM Materials by Aidite

Aidite offers a targeted portfolio of dental CAD/CAM materials intended for actual-world clinical and lab requirements. Every product is designed for excellent performance in digital applications. The product line features zirconia, resins, and polymers for full restorations, temporaries, and try-ins. These materials are chosen for simple processing, consistent aesthetics, and repeatable results for many different applications.

- 3D Pro Zir: A natural shade transition, multilayer zirconia with high strength and excellent esthetics. Indicated for restorations in the anterior and posterior segments.

- PMMA Disc: Resistant to polishing, durable, and offers color variety. Applicable for temporary crowns, full dentures, and provisional restorations.

- TRYIN Resin: Especially fabricated for try-ins for dentures. Offers precision and detailing for final adjustments before processing.

Aidite’s dental CAD/CAM materials ensure that labs and clinics achieve workflow efficiency without sacrificing quality or patient satisfaction.

How to Choose Dental CAD/CAM Materials

When choosing the CAD/CAM blocks, you should consider several clinical and lab factors. Let’s look at some of these factors upon which the right dental CAD CAM materials are selected:

- Restoration type: Different restorations have different requirements. For example, crowns require aesthetic strength while dentures are designed for long-term use.

- Function: Teeth have different functions in our mouth, so do the restorations. So when making restorations for molars, choose materials that are durable and strong.

- Material longevity: If you are making a temporary restoration, you can choose cheap materials but for a permanent one, always go for durable options.

- CAD/CAM system: The material you choose should be compatible with milling units and sintering stations

- Case objectives: Consider the requirements of patients, such as aesthetics, rapid turnaround, or budget-conscious.

Choosing Aidite streamlines the process by offering trusted, case-dependent materials. By considering case objectives and equipment capabilities, you can choose materials that are efficient and produce sound clinical results.

FAQs About Dental CAD/CAM Materials

What materials are used in CAD CAM dentistry?

Dental CAD/CAM materials include a wide range of materials. The main categories are ceramics, metal, hybrid, and polymer. These materials enable precision restorations in all clinical applications.

What is a CAD CAM crown made of?

A CAD/CAM crown is usually milled out of zirconia or lithium disilicate. Hybrid materials may be used in some situations to combine strength with aesthetic appearance, depending on clinical requirements.

How is cad cam used in dentistry?

CAD/CAM systems enable dental practitioners to design and create restorations digitally using a computer. This provides enhanced accuracy, shortened turnaround time, and a predictable outcome.

What materials are used in cad cam restorative?

CAD/CAM restorative materials include zirconia, lithium disilicate, PMMA, resins, titanium, and hybrids. In most cases, the material is selected based on the requirements, such as function, aesthetics, and duration, of the restoration being created.

Wrapping Up

Dental CAD/CAM materials are an integral component of digital dentistry. Regardless of the single crown or full-arch restoration, material selection directly affects durability, esthetics, and efficiency. Aidite offers products to suit actual clinical needs: zirconia for durability, PMMA for temporaries, and resin for try-ins. All dental CAD blocks promote precision and workflow speed while ensuring patient comfort and long-term outcomes. With knowledge of each material’s role, you can deliver restorations that meet both clinical and patient expectations. Stay ahead by choosing materials that perform with consistency and ease.