When it comes to replacing missing teeth, dentures remain one of the most popular options. But like any other thing, digitalization has also changed how they’re created. Traditional dentures require weeks of fittings and fine-tuning, whereas 3D printed dentures can be created, printed, and delivered within hours. But is speed always an advantage?

In this article, we’ll break down the comparison between 3d printed dentures vs traditional dentures. We’ll see how they compare not just in speed, but in precision, comfort, durability, and long-term value. If you’re wondering whether 3D dentures are worth it, or even how they work, this guide will give you a real answer.

What are 3d Printed Dentures?

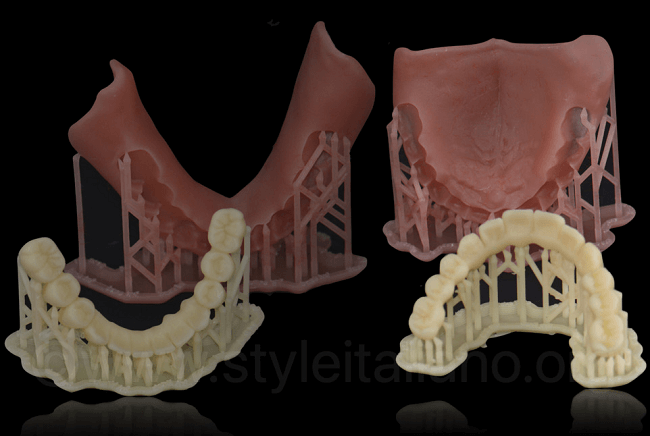

3d printed dentures are a modern replacement for traditional, hand-made dentures. Rather than utilizing physical molds and several manual processes, the method leverages computer scans and resin-based 3D printing. Hence, this method creates one-off dentures that fit much faster and more accurately.

How 3d Dentures are Made?

Here are the steps for 3d printing dentures:

- Step 1: The mouth of the patient is scanned with the help of an intraoral scanner.

- Step 2: Dentures are designed virtually using CAD software.

- Step 3: A 3D printer constructs the denture in layers with medical-grade resins.

- Step 4: The last step includes post-curing, polishing, and fitting.

When comparing 3d printed dentures vs regular dentures, the digital dentures offer quicker turnaround and more repeatable quality. So the answer to Can you 3d print dentures, is yes, and more and more labs and clinics are just doing that.

Why Use Aidite’s EZPRINT-P1 for 3d Printed Dentures?

Most 3D printers for dentistry promise speed and accuracy, but the EZPRINT-P1 is engineered specifically for the challenges of chairside production, where each hour counts and each micron impacts the fit.

Here are its noticeable features:

- With its clinical-grade accuracy (±30μm), you’ll need fewer remakes and post-op adjustments.

- Its rapid output speed enables single-arch dentures to be printed within 90 minutes, allowing for same-day delivery.

- Magnetic release platform reduces handling errors and maintains dimensional accuracy during the removal of the print.

- Full Aidite workflow compatibility means seamless integration with their intraoral scanners and curing systems, and no Frankenstein setups are needed.

Unlike generic 3D printers, the EZPRINT-P1 is optimized for dentures. That specialization matters. You’re not just buying a machine, you’re buying reliability under real-world pressure. It is backed by a complete ecosystem built around a 3d printed dentures vs regular dentures workflow.

What are Regular Dentures?

Regular dentures, also referred to as conventional or traditional dentures, are hand-crafted dental devices made from molds, wax models, and acrylic. They’ve been the norm for decades, and they get the job done. However, the process of making them is a labor-intensive one that’s time-consuming and heavily reliant on the technician’s technique.

How Regular Dentures Are Made

Let’s take a look at the steps to create traditional dentures:

- A physical impression is taken with putty-like material.

- Then, a wax mock-up model is made for bite and fit checks.

- Denture is shaped with acrylic resin and heat-cured.

- This process typically requires several adjustment visits.

Where They Still Work Effectively

Budget cases where time is not an issue.

Low-tech practices without scanners or printers available.

Patients with severe bone loss, where digital imaging might miss details.

Disadvantages of 3d Printed Dentures

But when 3D printed dentures vs regular dentures are compared, the disadvantages are obvious:

- Inconsistency: Minute mistakes in the mold process can result in a bad fit.

- Slow production: Turnaround will be 2–4 weeks, minimum 2–3 visits.

- No digital record: If the denture is lost or damaged, the whole process has to begin again.

Conventional dentures are still around, but they’re becoming less useful in the digital-first dental industry. With the progression of technology, the discussion is no longer just about price; it’s about control, accuracy, and patient experience.

3d Printed Dentures vs Regular Dentures

Deciding between 3D printed dentures vs regular dentures isn’t new vs old—it’s new vs better for your clinic and your patients. Let’s dissect:

Precision and Fit

- 3D Printed Dentures: Utilize digital impressions and print at micron-level accuracy. That translates to fewer sore spots, more efficient suction, and less chair time.

- Regular Dentures: Their manufacturing relies on physical molds that can distort. Their fit often requires multiple follow-ups and still may feel bulky or loose.

Durability and Material

- 3d Printed Dentures: Made from engineered resins that are designed to absorb pressure while resisting cracking. Some materials can even mimic natural gum textures.

- Traditional Dentures: Use heat-cured acrylic, which is strong but brittle. If you drop it once, you’re likely starting over.

Turnaround Time

- 3d Printed Dentures: They can be turned around in 24–48 hours using an efficient workflow.

- Regular Dentures: Will take a minimum of 2–3 weeks because of lab phases and back-and-forth tweaks.

Customization

- 3d Printed Dentures: It is simple to make adjustments to design, tooth color, or gum color with digital workflows and a few clicks.

- Regular Dentures: They have manual systems that are restrictive, which means you are stuck with what’s molded.

Cost Comparison

- 3d Printed Dentures: They are more expensive initially, typically starting from $500 per arch. But they save on long-term costs by limiting remakes and re-visits. Digital files also provide for quick reprints in case of lost dentures.

- Standard Dentures: Are less expensive initially, around $300, but tend to take more visits, relines, and hand-adjustments, costing more in the long run.

Are 3d Dentures Worth It?

If you’re weighing speed, accuracy, and long-term value, 3D dentures are definitely worth it. Sure, they cost a little more up front, but they save time. They cut the number of adjustment visits, and can be easily digitally reprinted. For labs, they provide quicker turnaround and greater output without increased staff. For clinics, they enhance patient satisfaction with improved first-fit accuracy. With platforms such as Aidite’s, the return on accuracy is more than worth the price.

FAQs About 3d Printed Dentures vs Regular Dentures

Are 3d printed dentures better than regular dentures?

Yes, they provide a more accurate fit, quicker production, and simpler replacements. They are best suited for clinics that want to minimize remakes and enhance patient comfort with digital precision.

How long do 3d printed dentures last?

With care, 3D dentures can last 5–7 years. The strength of resin is getting better, particularly with high-quality materials such as those of Aidite’s denture systems.

What are the advantages of 3d printed dentures?

They provide quicker turnaround, computerized copies for reprints, improved first fit, and fewer chairside adjustments, both convenient for labs as well as clinics.

Can you eat with 3d dentures?

Yes, they’re intended for complete daily function, including eating. Resins of high strength are strong enough to provide sufficient chewing support, just like traditional acrylic-based dentures.

What are the disadvantages of 3d printed dentures?

Some resins will be less natural-feeling than acrylic, and the initial equipment costs are higher. Moreover, not all clinics have digital workflows set up yet.

Conclusion

When comparing 3d printed dentures vs traditional dentures, the trend is obvious. Quicker manufacturing, improved fit, and long-term cost savings make 3D dentures a forward-thinking option for clinics and labs. Though traditional dentures continue to meet minimum requirements, they cannot compete with the accuracy and scalability of a digital process.Platforms such as Aidite’s EZPRINT-P1 facilitate that transition more smoothly, a purpose-built, high-precision denture print solution. It is designed for maximum efficiency, accuracy, and development. Upgrading with the right technology for 3D printed dentures isn’t only worth it; it’s necessary.