If you’ve been making regular dentures, you know how much stress the process involves. Several appointments, constant adjustments, and patients who are never satisfied. 3d printed dentures material is turning this all around. New materials provide you with improved results with less effort. Your patients receive dentures that fit from the very beginning. The process of making 3d printed dentures is quicker and more reliable than regular dentures. Learning about these materials will help you decide whether this technology is for your practice.

What Are 3d Printed Dentures?

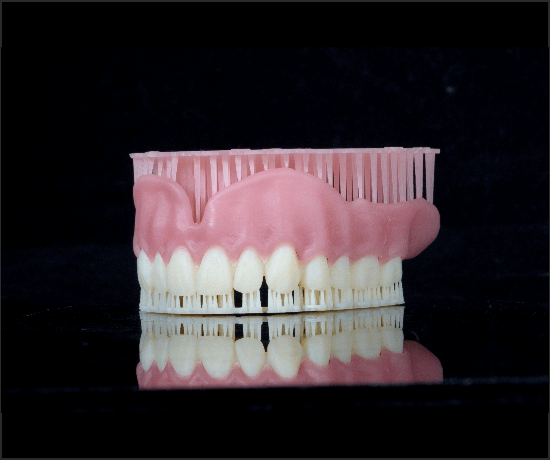

3D printed dentures are made with 3d printer rather than traditional laboratory techniques. It is surprisingly easy and offers you much more control over the finished product.

How the Process Works

• Take digital impressions with an intraoral scanner

• Design on the computer

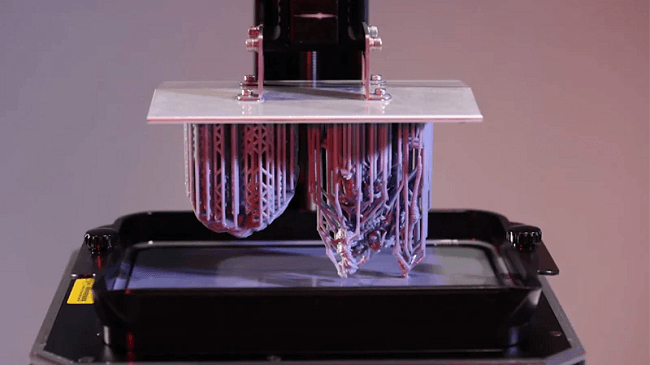

• Print them using special 3d printed dentures material

• Provide dentures that fit the first time

Benefits of 3d Printed Dentures

Regular dentures depend heavily on a lab technician’s skill. With 3d printed dentures, you cut out most of the issues. The material of the dentures is the same every time. The printing process is precise and reproducible.

Your patients feel the difference right away. The dentures are more comfortable because they’re made from precise digital impressions.

The entire process is quicker. While other dentures may take weeks, 3d printed dentures will often take days. Your patients enjoy the reduced treatment time, and you get to see more cases with less chair time per patient.

Common Materials Used For 3d Printed Dentures

Not every 3d printed dentures material is created equal. Various materials have distinct characteristics, and using the right one directly impacts the outcomes.

Photopolymer Resins

These are the most widely used 3d printed dentures material:

• Provide you with smooth surfaces and fine details

• Come in various shades to suit patient requirements

• Quick to work with and consistent results

Biocompatible Acrylics

They are comparable to traditional denture acrylics but made for 3D printing:

- FDA cleared for use in the mouth

- As compared to standard acrylics, they are tougher and resist breakage.

- Less likely to fracture under usual conditions

- Provide a comfortable fit for patients having regular dentures

Lucitone

Lucitone is a popular denture material that has been modified for 3d printing:

- Offers great color stability and aesthetics

- Stronger than PMMA materials

- Proven clinical performance

Titanium

Titanium is also used in 3d printing of some denture components:

- Extremely lightweight and strong

- Resistant to corrosion in the oral environment

- High cost but longer longevity

Nylon

Let’s look at the benefits of nylon for 3d printed dentures material:

- Comfortable for patients with sensitivity

- May require specialized printing equipment

Other resins

Here are some properties of advanced resin materials:

- Nano-filled composites with increased strength

- Can be customized for individual patients’ needs

Benefits of 3d Printed Materials

3d printed dentures material addresses actual problems you face on a daily basis in the case of dentures.

Improved Fit and Patient Satisfaction

- An accurate fit eliminates sore spots and pressure points

- You require fewer adjustment appointments

- Patients will adjust to their dentures quickly

- Less likely to experience retention issues

Improved Practice Efficiency

The 3d printed dentures material is consistent and delivers consistent results. You can make delivery appointments with assurance because the dentures will probably fit perfectly the first time. This saves you chair time and enhances patient flow in your office.

Material Properties

New denture material is stronger and more durable than before. Air bubbles and flaws that lead to cracking are prevented by the controlled printing. Dentures last longer and appear improved with time, according to patients.

Cost Benefits

Although the initial investment in equipment is substantial, the costs per case are less than with other methods. You save a lot of lab fees and time on adjustments. Patients are more satisfied, which translates into improved reviews and increased referrals for your business.

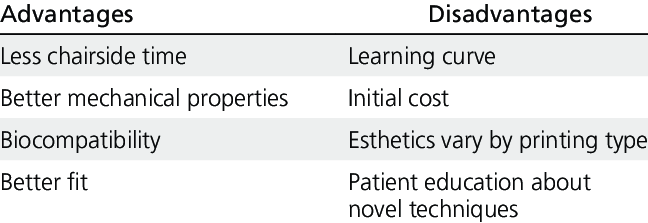

The learning curve is not too bad either. The majority of dentists learn the basics in no time, and the software becomes progressively simpler to use. Training by equipment manufacturers and material providers is available.

Limitations of 3d Printed Dentures Material

All technologies have their limitations, and 3d printed dentures are no different. Knowing these allows you to have realistic expectations and prevent possible issues.

Equipment and Setup Costs

- Initial printer and software investment is high

- Proper ventilation is required for certain denture material types

- Constant maintenance and calibration are needed

- Time and money required for staff training

Material Considerations

Present 3d printed dentures material does have some limitations you must be aware of. Certain materials are brittle if improperly handled during printing and finishing. Post-processing is paramount – poor curing can cause material failure or patient sensitivity.

Case Limitations

Not all cases of dentures are suitable for 3D printing. Extremely difficult cases with deep undercuts or bizarre anatomy may still be more easily worked with conventional techniques. The technology is most well-suited to simple complete denture cases.

Learning Curve Issues

The learning curve from the old ways is slow. You have to master new software, navigate printer settings, and establish new clinical workflows. Training staff is important because they work a different way than most dental assistants are accustomed to.

Some patients are suspicious of new technology as well. You may have to take the time to educate them on the advantages and dispel apprehension about “computer-made” dentures versus conventional techniques.

Aidite’s Denture Base Resin

Aidite is also a go-to source for quality 3d printed dentures material. Their denture base resins are specially formulated for dental 3D printing and provide predictable outcomes.

Material: Properties

- High durability and strength for long-term applications

- Good biocompatibility

- Colorfastness that does not change over time

- No odor and taste

Quality Control

Aidite is consistent batch to batch. This consistency is crucial when you’re establishing a 3D printing workflow. You know the material is going to behave the same way every time, so treatment planning is easier.

FAQ’s About 3d Printed Dentures Material

What are 3d printed dentures made of?

3d printed dentures are made from photopolymer resins, biocompatible acrylics, and hybrid materials. The options for materials in dentures cure in UV light, producing solid, robust prosthetics that fit accurately and withstand everyday chewing forces.

What materials are used in 3d printed prosthodontics?

3d printed prosthodontics use photopolymer resins, biocompatible acrylics, and hybrid polymers. These types of 3d printed dentures material differ in properties such as strength, flexibility, and aesthetics to suit different prosthetic applications and patient requirements.

What is the new material for 3d dentures?

The latest 3d printed dentures material consists of hybrid polymers and nano-filled resins. These have the best strength, flexibility, and biocompatibility. Companies such as Aidite are creating enhanced formulations with enhanced durability and patient comfort.

How do they make 3d dentures?

3d printed dentures are made by digital scanning, computer software design, and layer-by-layer printing with customized denture material. The UV light cures the 3d printed dentures into accurate, well-fitting prosthetics fit for patient wear.

How much 3d printed dentures cost?

3d printed dentures cost starts from $100. The price varies based on the materials used in the 3d printing. Premium materials cost more.

Conclusion

3d printed dentures material is a true upgrade from regular denture-making techniques. The technology produces improved patient outcomes with more streamlined workflows for your practice. Although there is a learning curve and initial equipment investment, the majority of dentists feel that the advantages far outweigh the obstacles. As technology continues to advance, 3d printed dentures will become the gold standard for full denture cases in the majority of practices.