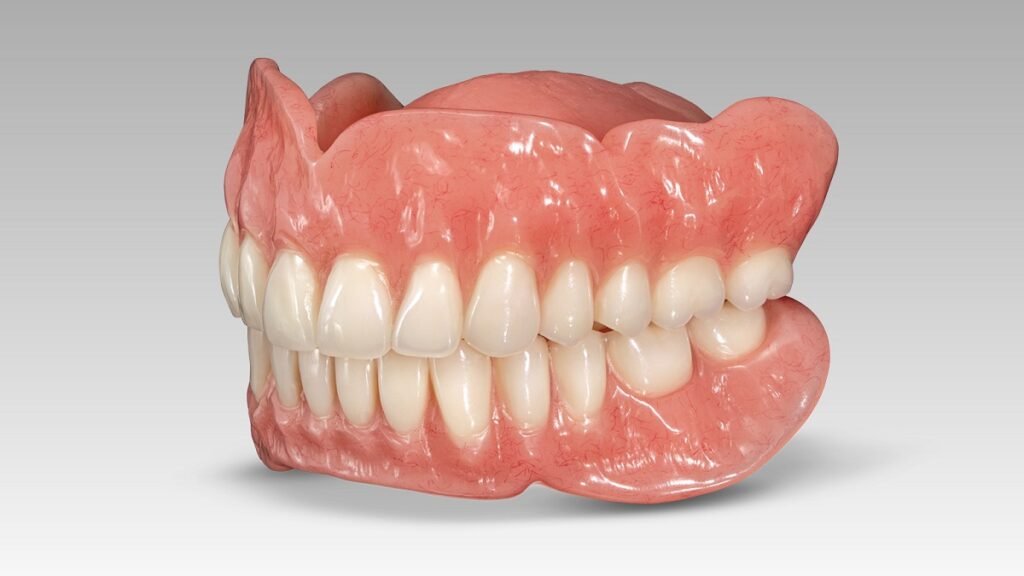

They change the modern digital dentures practices with high-level accuracy, effectiveness, and comfort. They differ in that they utilize advanced technologies, such as intraoral scanning for digital dentures, CAD/CAM denture design technology, and a simplified digital denture fabrication process. This unique method limits visits, enhances fit, and guarantees durable and aesthetic outcomes. Aidite spearheading a revolution with class-leading solutions, combining top-shelf materials and advanced technology. The conversation about digital dentures vs traditional dentures is not going away anytime soon, but the advantages of the digital method are hard to beat for both dentists and patients.

What Are Digital Dentures?

Digital dentures are designed using digital technologies, such as three-dimensional (3D) scanning, computer-aided design (CAD), and computer-aided manufacturing (CAM). Compared to regular dentures, digital dentures make the procedure easier with fewer appointments and an automatic impression, thus allowing an immaculate fit and aesthetics.

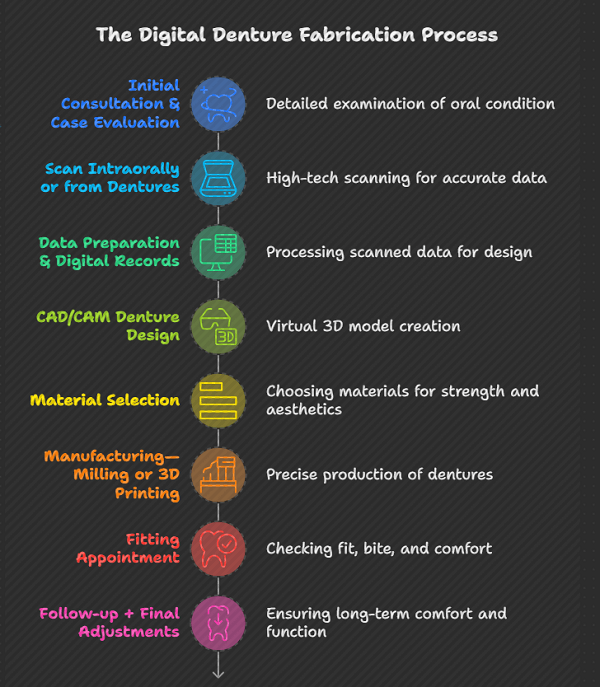

How To Make Digital Dentures

Intraoral or denture scanning replaces traditional impressions, which can be a mess. This marks the beginning of the digital denture fabrication process. CAD/CAM software applies scan data to create custom dentures, which are then milled or 3D printed. It allows you to reduce mistakes, chair time, and reproduce simple things when needed with accuracy, aesthetics, and durability.

Step 1: Initial Consultation & Case Evaluation

A detailed examination of the oral condition of the patient must be carried out to formulate a thorough and detailed treatment plan before the digital dentures are fabricated.

- In a denture consultation, a dentist assesses the patient’s oral health and denture requirements.

- Previous dentures, the anatomy of the mouth, and the bite are examined.

- A treatment plan for the digital denture fabrication process.

Step 2: Scan Intraorally or from Dentures

High technology scanning technology is used instead of impressions for better accuracy in digital data collection.

- Dentists use either intraoral scanning for digital dentures or rebut decoding already existing dentures.

- This creates 3D digital images to take the place of traditional messy impressions.

- It scans the soft tissues, gums, ridges, and bite with plenty of details.

Step 3: Data Preparation & Digital Records

After scanning has been completed, the gathered data needs to be processed to ensure accurate data during the designing stage.

- The scanned feeds are arranged, validated, and designed, geared up for the design process.

- These digital copies are also kept for design, fabrication, and future use.

- This will help in case duplication of the dentures is needed.

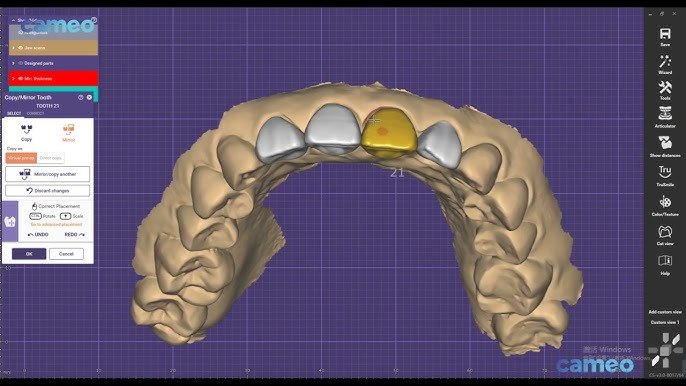

Step 4: CAD/CAM Denture Design

The digital setting phase is very specific with the use of some advanced software.

- These scanned data are imported into CAD/CAM denture design technology.

- They will then have the dental technicians prepare a virtual 3D model of the dentures.

- These designs are tailored for patient fit, function, bite, and aesthetics.

- More accurate virtual try-ins can be simulated.

Step 5: Material Selection

The materials used can impact the fitness of the completed dentures, their comfort, and their appearance.

- The materials are chosen for strength, aesthetics, and biocompatibility.

- The materials could be high-end polymers, acrylic resins, or ceramics.

- Materials tailored for digital denture needs, such as the high-end materials offered by Aidite, are available.

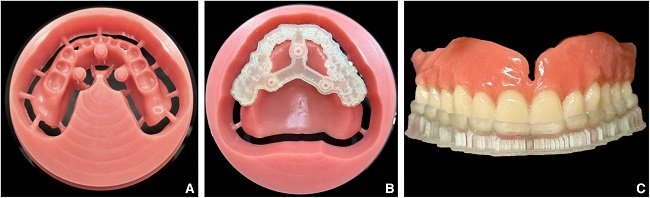

Step 6: Manufacturing—Milling or 3D Printing

The final design is produced with high precision by modern milling or 3D printing technologies.

- The ultimate design is dispatched for manufacturing.

- These milling machines will take a block of material and carve the denture from it.

- On the other hand, dentures are printed layerwise using the 3D printer.

- With a digital denture fabrication process, we can guarantee precision, reproduction, and fewer mistakes.

Step 7: Fitting Appointment

The final dentures are tried in the patient, and the dentist checks the fit.

- At the time of denture delivery in the patient

- Checks the fit, bite, retention, and comfort of the unit

- These are minor adjustments to ensure that function is perfect and patients are happy.

Step 8: Follow-up + Final Adjustments

Follow-up appointments are important in confirming that comfort and function are sustained over the long haul.

- Follow up visits are used to monitor the patient.

- All other tuning is done for the long haul comfort level.

- The digital file stays in storage for duplication when necessary.

The Role of CAD/CAM Denture Design Technology

However, today, we use the CAD/CAM denture design technology to accurately create a virtual image of the anatomy of a patient’s mouth, which will allow for fitting of even the most complex anatomy. This enables rapid changes with fewer in-person visits with the patient. When paired with Aidite′s high-quality milling machines and materials, it achieves impeccable results.

- Precision and Accuracy: Denture design technologies, CAD/CAM denture design technologies, can provide even the smallest details of anatomy. These systems will also ensure precision in design for a better fit and comfort.

- Customization: Each denture is tailored to the patient’s needs, which means you can alter the shape, size, and position of the teeth.

- Time Efficiency: By transferring the design and production to a digital workflow, these treatments can be delivered with reduced design and production time, fewer patient appointments, and faster delivery.

- Repeatability and Reproducibility: Digital records are easily stored and accessed, which means that if a denture needs replacing or a repeat denture needs to be made, they can be reproduced exactly.

- Blending with Contemporary Materials: These systems can capture even the finest details of the anatomy, ensuring high precision designs and thus better fit and comfort with CAD/CAM denture design technologies.

Advantages of Intraoral Scanning for Digital Dentures

There are many advantages of using Intraoral scanning for digital dentures that improve patient experience and clinical outcomes.

- Improved patient comfort: More comfortable for the patient.

- Enhanced accuracy images are taken for better-fitting digital dentures.

- Reduced turnaround time: Digital data immediately speeds up the digital denture fabrication process.

- Immediate data availability: Scans are available immediately after scanning for CAD/CAM denture design technology, eliminating waiting time.

- Better patient communication: Doctors have been keeping their patient communication top-notch; 3D image scans give better visualization, helping patients understand the treatments they will undergo in a better way.

Aidite intraoral scanning for digital dentures has never been quicker or more predictable, delivering superior intraoral scanning, ensuring a smooth dental experience while maintaining a pleasant experience for patients.

Digital Dentures vs Traditional Dentures: An In-depth Overview

| Feature | Digital Dentures | Traditional Dentures |

| Impression Process | Digital denture intraoral scanning is quick, comfortable, and accurate | It needs dirty, sweaty physical impressions |

| Design Process | Using high precision CAD/CAM denture design technology in the production process. | Potential for human error as the design is manual. |

| Fabrication Time | More efficiency with a digital denture fabrication process. | Production time is longer and requires several visits by the patient. |

| Fit & Comfort | Great fit, less adjusting needed | Usually needs to be tried on and altered several times. |

| Reproducibility | If lost or damaged, digital files can be reproduced easily. | Usually need to be completely remade if lost or damaged. |

| Aesthetics | Delivery of a better look with accurate digital precision | Not enough customizability. |

| Record Keeping | Digital records for the future are permanent. | Tangible media that can be lost or destroyed. |

The Future of Digital Dentures

Dental practitioners are quick to embrace the precision and efficiency of digital dentures, adopting them at an impressive pace. Improvements in CAD/CAM denture design technology & Intraoral Scanning for digital dentures are persistently making digital dentures for the patients more usable, accurate, & durable.

- Increased Global Adoption: More and more dental clinics are embracing digital dentures due to increased efficiency, accurate manufacturing, and higher patient satisfaction.

- Advancements in CAD/CAM Denture Design Technology: In the future, with CAD/CAM denture design technology further developed, more precise and personalized dentures will be designed.

- Enhanced Intraoral Scanning for Digital Dentures: The future of intraoral scanning for digital dentures will be faster, more accurate, and more comfortable.

- Enhanced materials and durability: As we have seen with many of Aidite’s latest materials, they strengthen, increase longevity, and the aesthetic will become more natural.

- Seamless Integration through AI and Automation: The design and automation of fabrication by the power of AI will enable the integration of the digital denture fabrication process.

How Digital Dentures Improve Patient Experience

Digital dentures also minimize chair time and appointment time for the dentist so that you can have your dentures done quicker and more comfortably. Messy scans are replaced with intraoral scanning and combined with CAD/CAM denture design technology for the definitive restoration; a precise fit can be achieved with little to no chairside adjustment needed. Digital dentures offer comfort, aesthetics, and longevity over other traditional solutions.

- Reducing Appointments: The digital denture fabrication process is time-efficient, so it reduces treatment times as well as appointments for adjustments and fittings.

- Comfortable Scanning Process: This, of course, replaces those inexact and messy conventional impressions with which your patients are so familiar and introduces intraoral scanning for digital dentures into the mix, all of which ensures patient comfort.

- Better Fit, More Comfort: The precision with which these dentures are designed thanks to CAD/CAM denture design technology has lead to a reduction in sore spots and adjustment appointments.

- Faster Turnaround Time: It is extremely quick, and the patient receives their digital dentures much earlier than with the conventional technique, giving restoration of the lost function and aesthetics much earlier.

- Standardization of quality and appearance: The level of accuracy in digital dentures provides consistent results with high quality, which makes your patient feel more satisfied and confident.

FAQs

Q1. Why are digital dentures more accurate than traditional dentures?

Intraoral scanning is used to replace the conventional impression; CAD/CAM denture design technology using digital dentures records the true 3-D surfaces of the structures and thus overcomes the errors of a manual impression.

Q2. How long does the digital denture fabrication process take?

The digital denture fabrication process is usually completed with fewer appointments than conventional dentures and can often be provided within a few days to 2 weeks.

Q3. Are digital dentures more comfortable to wear?

Yes, because their denture design uses CAD/CAM denture design technology to create a precise fitting denture, which reduces the chance of sore spots, decreases the need for adjustments, and improves patient satisfaction and confidence.

Conclusion

Digital dentures are a breakthrough solution in modern dentistry, providing better precision, comfort, and quicker turnaround time than the traditional method. Due to innovations like intraoral scanning for digital dentures, CAD/CAM denture design technology, and a streamlined digital denture fabrication process, the overall patient experience is better with long-lasting, natural-looking results. While the benefits of digital solutions vs traditional dentures are apparent, as technology advances, digital dentures will be increasingly more widely available and can replicate a beautiful smile faster, easier, and with a better fit than ever. The professionals behind trusted companies like Aidite excel in providing high-quality dental materials and digital solutions.