In the fast-paced world of dentistry today, the digital denture workflow has emerged as a foundational approach to providing exact, efficient prosthetics. At the core of this is the incorporation of cutting-edge technologies, such as the Aidite A-IS Pro dental scanner, supporting both aspects from impressions to final production. By applying such advances, the practitioner can help achieve improved precision, speed, and patient satisfaction in the digital denture process.

The Digital Denture Workflow Explained

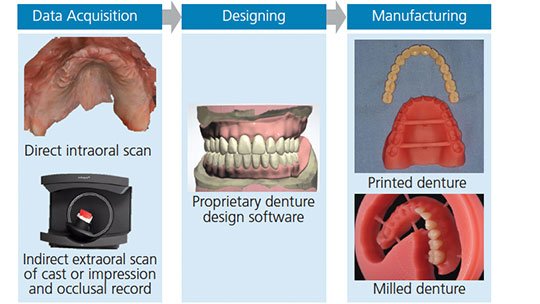

The digital denture workflow includes various stages, during which digital tools are used to create and manufacture dentures. By doing this, manufacturers can use machines to do the work, which ensures both accuracy and consistency.

The Fundamentals of a Digital Denture Process

- Intraoral Scanning for Digital Dentures: Aidite’s A-IS Pro allows clinicians to produce highly detailed 3D images of the patient’s oral cavity during intraoral scanning for digital dentures. This allows dentists to get better, more comfortable results from digital impressions for dentures.

- Digital Impressions for Digital Dentures: Using digital methods, digital data replaces the traditional impression and is the basis for designing the digital dentures workflow.

- Digital Denture Design: In a CAD/CAM denture fabrication workflow, software engineers design the denture to exactly match the unique needs of the mouth.

- CAD/CAM Denture Production Process: The design for the denture is produced using CAD technology, and the final design is fed into a CAM tool that makes high-quality dentures that are predictable.

Introducing digital tools allows dental practices to unite various stages of denture work and achieve a more efficient digital denture workflow that is better for patients.

Role of Aidite A-IS Pro in Digital Denture Workflow

The Aidite A-IS Pro dental scanner contributes to the performance of the digital denture workflow. Its advanced characteristics support precise data capturing, which is absolutely indispensable for the success of digital impressions for dentures and the digital denture design process.

Notable Features:

- Rapid Scanning: Occlusion scans can be completed in 8 seconds and full impressions in 58 seconds, considerably minimizing chair time and also the full time within the chair in the CAD/CAM denture fabrication process.

- High-Resolution Texture Scanning: Densely captures color textures for the visual enhancement of oral structures, enabling superior digital impressions for dentures.

- The Function of Dynamic Scanning: Swing of scan head 0-5 degrees, accurately acquiring the status of the articulator, and performing modeling more accurately in the digital denture design process.

- Open System Compatibility: Compatible with STL, OBJ, PLY formats, capability to be integrated with any CAD/CAM denture fabrication workflow and production.

- Compact and Durable Build: The Aidite A-IS Pro is designed to handle the demands throughout the digital denture workflow with durable construction for years of reliable operation.

- Noise Reduction Technology: Works quietly to create a more peaceful environment for the clinic and patients during the digital denture workflow.

By adding the Aidite A-IS Pro to your practice, you can unleash the full power of the complete digital denture process.

Benefits of Aidite A-IS Pro in Digital Denture Workflow

Adopting a digital denture workflow, like the Aidite A-IS Pro, has several advantages:

- Increased Precision: You can expect the same exceptional precision with digital impressions for dentures to create a more comfortable denture.

- Enhanced Patient Comfort: Non-invasive intraoral scanning with digital dentures means no more mess and gagging.

- Quick Turnaround: A quicker CAD/CAM denture fabrication workflow equals faster delivery.

- Quality that Lasts: Digital workflows guarantee consistent quality in all digital denture design process.

- Cost-Effective: The savings from material waste and manual labor enable you to profit over the long haul.

- Ultra High Definition: Ultra accurate data for the digital denture design process.

- Real-Time Feedback: Archiving scanned data with immediate review can rapidly shorten the errors and accuracy of digital impressions for dentures.

These benefits can also contribute to the reasons why more and more clinics/shops would like to go for a digital denture workflow with Aidite A-IS Pro.

Step-by-Step Process: From Scanning to Denture Fabrication

The transition from the acquisition of digital impressions to the delivery of a removable denture is then composed of linked activities. Each step offers accuracy, customization, and effective production in the digital denture workflow.

- Patient Assessment and Preparation: The practitioner assesses the patient’s oral suitability for the appointment and medical history. Any pre-prosthetic treatments that are required are scheduled. The mouth is cleaned, and reference points are established to facilitate optimal scanning.

- Digital Dentures Intraoral Scanning: The dentist takes high-definition 3D scans with the aid of A-IS Pro. This records fine details of the gums, ridges, and neighbouring teeth, resulting in the most accurate digital replication later.

- Digital Impressions for Dentures: This digital scan of your mouth is converted into a digital impression in seconds, so no more gooey messes of traditional materials. This creates a precise digital twin of the oral anatomy, which is ready for virtual design.

- Data Import into CAD Software: The digital scans are imported into CAD software. Such software is suitable for the Aidite system and allows a professional to see, modify, and enhance the base form.

- Digital Design of Denture Process: The lab technicians and/or dentists digitally design the denture based on the denture base, teeth arrangement, and occlusal positions. Smart tools such as AI generated design suggestions and anatomical libraries provide for a denture that is functional and aesthetic.

- CAM File Preparation: The design is exported in formats such as STL or PLY, suitable for CAM systems. These files include nesting and toolpath optimization to make the fabrication process more efficient.

- CAM Production: The physical denture is milled or printed in milling machines or 3D printers using PMMA or dental compliant material. In this way, very high precision and uniform quality result as expected in a CAD/CAM denture fabrication workflow.

- Post-Fabrication: The denture is polished, adjusted, and occasionally stained post-fabrication for aesthetics and comfort.

- Fitting and Adjustments: The Clinician places the denture in the patient’s mouth. Bite, stability, and comfort are assessed, and the necessary adjustments are performed in the chair.

- Delivery/Patient Education: The Denture is delivered to the patient. Usage, hygiene, and maintenance instructions are included for long-term use.

The digital denture workflow involves a sequence of procedures whereby dentures are designed and manufactured using digital technologies. This method limits human doing and therefore is likely to produce a reduction of errors while increasing the consistency.

FAQs

Q1: How good are digital dentures vs Traditional dentures?

The digital dentures made according to a full digital denture workflow are very accurate because the digital dentures are based on an accurate intraoral scanning for digital dentures and CAD/CAM production. This leads to an improved fit, function, and comfort that can be offered by conventional means.

Q2: How long does it take to make a digital denture?

The digital denture design process and the automated CAD/CAM denture fabrication workflow make it possible to finish the digital denture in much less time (in only a few days) than would be required for completing a traditional denture (7-9) weeks.

Q3: Can digital denture impressions eliminate the need for traditional molds?

Yes, digital impressions for dentures using a device such as the Aidite A-IS Pro provide a clean, accurate, and patient-friendly alternative to the traditional impression trays. In modern dental clinics, they’re gradually replacing physical molds.

Conclusion

With the digital denture workflow of Aidite A-IS Pro, speed, accuracy, and better patient results are now available for modern prosthodontics. Regardless of whether it is intraoral scanning for digital denture, digital impression for denture, or CAD/CAM denture fabrication workflow, Aidite is updating every step of the procedure. With this technology, dental professionals can not only push the digital denture design process in every direction.