Poor-fitting of crowns and bridges and severe tooth decay are the common problems every dentist faces when they are not equipped with a dental furnace. Using a traditional method to heat the material causes inappropriate heat distribution. It led to slowing down the dental process, and the material is harder to mold.

Models made from this material break easily and need replacement. So, the dental lab furnace saves you from all these pesky hassles. It helps to heat materials to the right temperature. So they can be molded and hardened perfectly.

However, dental furnace uses are not limited to heating up the material. Let’s explore the other dental furnace uses in dentistry and key factors to make a worthy investment.

What Is a Dental Furnace and Why Is It Essential?

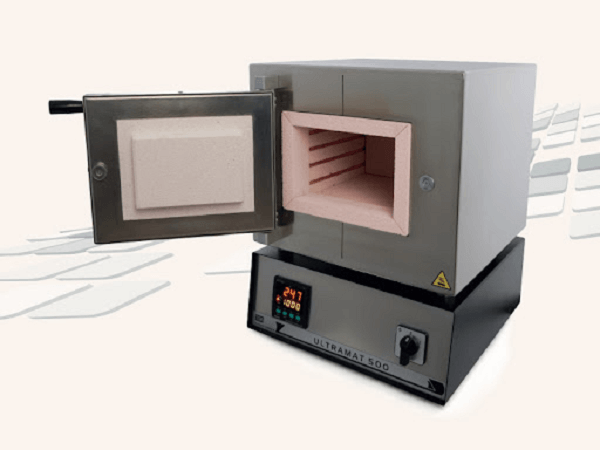

A dental furnace is a special machine used by dentists and dental labs. It helps heat up materials that are used in dental work. These materials can include metals, ceramics, and porcelains. The furnace makes the materials strong and hard so they can be used for crowns, bridges, and other dental restorations.

The zirconia Dental Furnaces for hospitals is essential because it ensures the materials have the right strength and fit. The furnace helps dentists do their jobs well and gives patients high-quality care.

The basic components of a dental furnace are:

- Heating Chamber

- Control Panel

- Temperature Sensor

- Power Supply

- Cooling System

Understanding the Different Types of Dental Furnaces

Generally, there are three different types of dental lab furnaces in dental labs for different material specifications. Let’s explore the details of each dental furnace uses.

– Ceramic Combination Furnaces

This dental casting furnace is a versatile piece of equipment used in dentistry. You use this furnace to perform multiple tasks like firing and baking materials for crowns, bridges, and veneers. This furnace ensures that ceramics are heated to the perfect temperature for a durable finish. It also includes features like a vacuum system.

Pros:

- It can be used for multiple tasks, making it versatile.

- This furnace is great for creating durable ceramic restorations.

- You can easily control the temperature for precise work.

- The dental furnace is used to reduce the chances of errors or imperfections.

Cons:

- This furnace is costly and out of the range for smaller dental labs.

– Sintering Furnaces

This furnace is designed to heat dental materials until they become solid. This type of furnace is particularly important for metals and ceramics. It ensures these materials bond tightly together to become strong. Sintering furnaces can reach very high temperatures, often over 1600°C. It enables dental professionals to fuse materials properly.

Pros:

- You can create strong, durable dental materials.

- This furnace works with both metals and ceramics.

- It reduces the chances of materials shrinking or warping.

- The restorations produced are of excellent fit and strength.

Cons:

- It requires careful monitoring to avoid overheating materials.

– Burnout Furnaces

You can use this dental wax burnout furnace to remove wax or plastic patterns from dental molds. This process is essential when creating metal castings for crowns and dental restorations. Burnout furnaces are designed to heat at high temperatures, typically between 700C and 1000°C. This type of furnace often comes with a built-in timer to ensure the burnout process is carried out correctly.

Pros:

- This is crucial for creating accurate molds for metal castings.

- Ensures no wax or plastic residue is left behind, leading to clean, precise castings.

- It is easy to use with simple temperature control.

- It saves time by speeding up the casting process.

Cons:

- The burnout process can sometimes be out of control due to high temperatures.

Top 5 Dental Furnace Uses in Restorative Dentistry

Dental furnaces are essential tools in restorative dentistry. Here are the top five detailed Dental Furnaces uses in restorative dentistry.

– Sintering Ceramic Crowns and Bridges

Dental furnace uses include sintered ceramic crowns and bridges. Then, change these materials into durable restorations. These furnaces reach high temperatures, sometimes over 1600°C. It ensures the ceramic materials bond tightly and become strong.

To use the furnace, the dentist places the ceramic crowns or bridges in the furnace. The furnace heats the materials for a set amount of time, depending on the type of ceramic.

– Firing Porcelain Veneers and Inlays

Dental furnaces are also used to fire porcelain veneers and inlays. Firing is the process of heating porcelain to a high temperature to give it hardness. This is important for creating veneers and inlays that will last in the patient’s mouth. The dental furnace uses include helping shape the porcelain into the right form.

To use the furnace, the porcelain pieces are placed inside, and the furnace gradually heats up. The temperature and time are adjusted based on the type of porcelain being used.

– Metal Bonding for Prosthetics

Zirconia dental furnaces for hospitals are also used for metal bonding in prosthetics. This process is used to bond metal parts to ceramics, making them stronger and more durable. When a dentist needs to create a prosthetic model, the furnace helps to bond the materials together.

The furnace melts the metal to a specific temperature. It allows the metal to bond with the ceramic material. This is important for creating prosthetics that acquire both strength and a natural look from the ceramic.

– Creating Accurate Molds for Casting

Dental furnace uses include creating accurate molds for metal casting. When dentists need to create metal crowns or bridges, they first use a wax pattern that is placed in the furnace. The furnace then heats up, burning away the wax and leaving an empty mold behind.

This mold is then filled with molten metal to create the restoration. Using a furnace ensures that the mold is clean and accurate. This helps create a prosthetic that fits the patient perfectly and lasts longer.

– Smoothing and Polishing Dental Materials

Dental furnace uses include smooth and polished dental materials. After a restoration has been made, it may need to be smoothed out to fit the patient’s teeth perfectly. The furnace can be used to heat the material to shape it with ease.

The heating process makes the materials easier to work with. It improves the final look and fit. After the material cools, it will have a smooth surface that is comfortable for the patient.

Top 3 Cost-Effective Suppliers of Dental Furnaces to Increase Your Dental Workflow

Here are three manufacturers of dental lab furnaces that provide durable devices without breaking the bank.

1. Aidite

Aidite is a well-known supplier in the dental industry. It provides a wide range of affordable and high-performance dental furnaces. Aidite focuses on providing furnaces designed for ceramics, sintering, and metal bonding.

The Aidite CSF-400 Sintering Furnace is perfect for sintering zirconia and other common materials. It provides a high-temperature range and precise control over sintering cycles. Its touchscreen controls enable you to control the whole process and reduce the errors.

2. Ivoclar Vivadent

Ivoclar Vivadent is a leading global supplier of dental products. The brand mainly focuses on cutting-edge technology and reliability. Their furnaces are designed to work with a variety of materials.

You can sinter ceramics and zirconia with high precision. The furnace features a powerful heating system. This system ensures the even distribution of the heat. So you can achieve strong and durable dental restorations.

3. Renfert

Renfert is another trusted supplier of dental furnaces. Their products are known for their durability, efficiency, and precision. Their furnaces are suitable for a variety of tasks, including sintering, firing, and burnout processes.

The user-friendly design of their furnace enables you to easily operate it. You can adjust the temperature according to different settings. Their furnace can reach high temperatures of up to 1600°C.

Frequently Asked Questions

What is the use of a furnace machine?

The basic purpose of this machine is to shape the dental material. The working process of the machine starts with melting the metals for casting or heating the material. Then harden the material to shape according to the dental restoration type.

What is the temperature of a dental furnace?

The temperature of the dental furnace depends on the nature of the material you used in the device and furnace types. Typically, dental furnaces reach extremely high temperatures between 1450°C and 1600°C to sinter zirconia material.

What is the principle of a dental furnace?

The dental furnace is basically used to create hard ceramic restorations like crowns and veneers. You can apply controlled heat to the material and enable the sintering and glazing process. It enhances the material’s strength and durability.

Final Thoughts

To sum up, dental furnace uses vary with different dental industry requirements. In some dental labs, health care professionals use this device to mold and shape the dental material. This device uses a certain temperature level to heat up the material. Different materials require different heat requirements.

So, it’s essential for you to understand the material specification and heat compatibility before shaping and molding in the dental furnace. Otherwise, the material will not mold easily, and dental models made from this material require a high level of adjustment. You need to spend hours fitting the model according to the patient’s mouth shape and size.