Using advanced dental materials can enhance your practice and provide the best results for your patients. Biomic Lisi Connect is a new-generation material for aesthetic restorations and high performance. Whether you are a beginner or a professional, it is important to know how to use this product correctly to achieve the best outcome.

Here, you will find all the information necessary to understand how to use Biomic Lisi Connect properly: preparation, application techniques, and more – to achieve high accuracy and durability of your dental restorations.

What is Biomic LISI Connect?

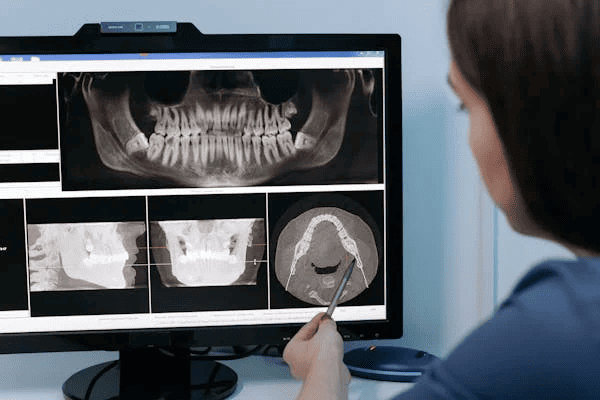

The Biomic Lisi Connect is a revolutionary dental tool that transforms zirconium surfaces into fine, resilient, and lithium disilicate-coating. Zirconia dental crowns are renowned for their durability and aesthetic appeal, but advancements in dental technology have taken them to the next level. By seamlessly integrating into the sintering process, thereby enhancing the crown’s strength and longevity, allowing it to last up to 10–15 years.

How to Use Biomic LISI Connect?

Step 1. Spray evenly for uniform coverage

Just like an artist preparing a canvas, dental professionals must create a flawless base. A layer of the LiSi Connect should be sprayed accurately and consistently to ensure the lithium disilicate coating forms uniformly after sintering, enhancing the surface modification process.

Key Measures: To ensure optimal results, apply a consistent layer across the zirconia bonding surface. Use a specialized sprayer designed for Dental Care applications to avoid uneven coverage. Start by holding the sprayer at a moderate distance (around 10–15 cm) from the zirconia surface. Begin with light, even strokes, ensuring that every part of the surface is coated without overloading or pooling. Avoid spraying too thickly, as this could lead to irregular crystallization during sintering and might hinder proper bonding.

Also, work in a clean, dust-free environment to prevent contaminants from settling on the sprayed surface. Any impurities could interfere with the bonding process and compromise the coating’s integrity. Lastly, inspect the zirconia restoration under good lighting to confirm that the coating appears even and smooth.

Step 2. Follow the correct sintering curve

Similar to baking a cake, time management is important. Ensuring precise temperature is also crucial so as to avoid overheating. Deviations can affect the crystallization process, or even weaken the zirconia or disrupt the intended surface morphology thereby leading to an unsuccessful procedure.

Key Measures: The sintering process is critical for transforming LiSi Connect into a durable lithium disilicate coating. Follow the specified sintering temperature and time curve provided by the manufacturer without deviating. Using a calibrated sintering furnace, preheat the zirconia to the recommended starting temperature.

Gradually increase the heat according to the curve, ensuring the temperature does not spike too quickly. This approach allows the coating to crystallize properly and penetrate the zirconia surface. Importantly, monitor the cooling phase as abrupt cooling can create thermal stresses that weaken the zirconia or cause microcracks in the coating. Ensure the furnace is functioning properly by performing regular maintenance and calibration checks.

Step 3. Optimize the acid etching process

Acid etching creates the rough, porous surface essential for optimal bonding. Think of it like sanding wood before painting—without it, the adhesive won’t adhere properly. A well-etched surface ensures that the zirconia restoration bonds securely, mimicking the bonding strength of glass ceramics for a reliable, long-lasting dental restoration.

Key Measures: After sintering, the zirconia surface requires acid etching to prepare it for bonding. Depending on the strength of the hydrofluoric acid (HF) used, the etching duration will vary:

- For 4.5% HF, etch the surface for 90–120 seconds.

- For 9.5% HF, etch for 45–60 seconds.

It’s vital to apply the acid uniformly across the zirconia surface using a fine applicator or brush. Avoid applying excessive amounts, as pooling can lead to inconsistent surface roughness. Once the etching process is complete, rinse the zirconia thoroughly with deionized water to remove all acid residues. Follow up with an ultrasonic cleaner if possible, as this ensures every pore is free of debris. Finally, dry the surface with clean, oil-free compressed air to prevent contamination

Step 4: Choose the right resin-based adhesive: Adhesives are the final glue that holds the restoration together. A poorly chosen adhesive or improper application can result in weak bonds, leading to premature failure of the crown. Using a pure light-type resin adhesive not only ensures a strong bond but also maintains the restoration’s natural appearance, avoiding the darkening effect often caused by suboptimal materials. This step ensures both durability and aesthetics, critical for patient satisfaction.

Key Measures: Remember, the choice of adhesive plays a pivotal role in the zirconia restoration process. Use a resin-based adhesive with a proven track record for zirconia bonding. Opt for a pure light-type resin adhesive when aesthetics are a priority, as it prevents discoloration over time. Before applying the adhesive, ensure the etched zirconia surface is completely dry and free of contaminants.

Apply a thin, even layer of adhesive using a microbrush, ensuring complete coverage of the bonding surface. Avoid applying too much adhesive, as excess material can seep out during placement and complicate the finishing process. Once the adhesive is in place, cure it thoroughly with a high-quality curing light, ensuring the recommended exposure time is met.

How to Prevent Contamination & Bonding Issues?

To learn how to use Biomic LiSi Connect effectively and prevent contamination, always handle it with gloves and ensure the work area is clean and free of dust and debris. After preparing the zirconia surface, clean it thoroughly with deionized water and dry it using oil-free compressed air.

When spraying, maintain a consistent distance and apply light, even coats. Avoid over spraying to ensure a thin, uniform layer. Follow the manufacturer’s sintering instructions precisely, using a calibrated furnace to maintain consistent temperatures throughout the process.

Regularly clean and maintain your equipment from time to time, including sprayers and furnaces, to prevent buildup or malfunction that could compromise results. These steps ensure predictable outcomes and high-quality surface modification.

Why Biomic LISI Connect Is the Best for Zirconia Bonding

When it comes to dental restoration, accuracy, and durability are essential. This is where Aidite Biomic LiSi Connect stands out. As a trusted name in dental solutions, they have developed a product that simplifies zirconia bonding and also improves its longevity and performance. Here’s why it is the best choice for zirconia bonding.

- User-Friendly Application: Made for easy use, no complexity. Designed to simplify zirconia bonding. Knowing how to use Biomic LiSi Connect was never this easy.

- Unmatched Bonding Strength: Indeed an excellent choice when it comes to creating long-lasting durable dental restorations, ensuring patients their smile and peace of mind for years to come.

- Reliable Performance: Tested and trusted by dental professionals worldwide, it is a product you can count on.

FAQs

What type of dental crowns are there?

Dental crowns are of different types, and they vary according to their unique properties. You can be rest assured the different crowns are made to suit your comfort. Here are the main types:

- Porcelain

- Metal crowns

- Zirconia crowns

- PFMs

- Resin

How long do dental crowns take to settle?

Usually, dental crowns take a couple of days to settle. In most cases, it could take longer, perhaps a few weeks. At first, patients might feel discomfort around the mouth region which is normal as they tend to adjust as the surrounding tissues adapt to the crown’s presence.

Can dental crowns be replaced?

Yes. The process of replacing old dental crowns is just as easy as the original crown process. Crowns can be replaced for several reasons which are; Inadequate fit, damage, wear and tear or even aesthetics.

Is zirconia crown material good for a tooth crown?

Yes. They are made to be very durable, and long-lasting, have unique aesthetics and also provide comfort. Zirconia crowns have superior strength and they are a perfect fit for patients with allergies for PFM crowns.

Conclusion

The Biomic LiSi Connect offers an innovative solution for zirconia restorations, creating a durable lithium disilicate coating that enhances bonding strength and extends the crown’s lifespan. This guide has provided detailed steps on how to use Biomic LiSi Connect, from applying an even spray layer to mastering the sintering and etching processes. By following these best practices, Dental Care professionals can achieve results comparable to glass ceramics, ensuring long-lasting and aesthetic restorations.

For professionals seeking efficiency and patients demanding longevity, the LiSi Connect is a game-changer. Highly recommended is Aidite, a trusted provider of quality dental solutions, ensuring exceptional.