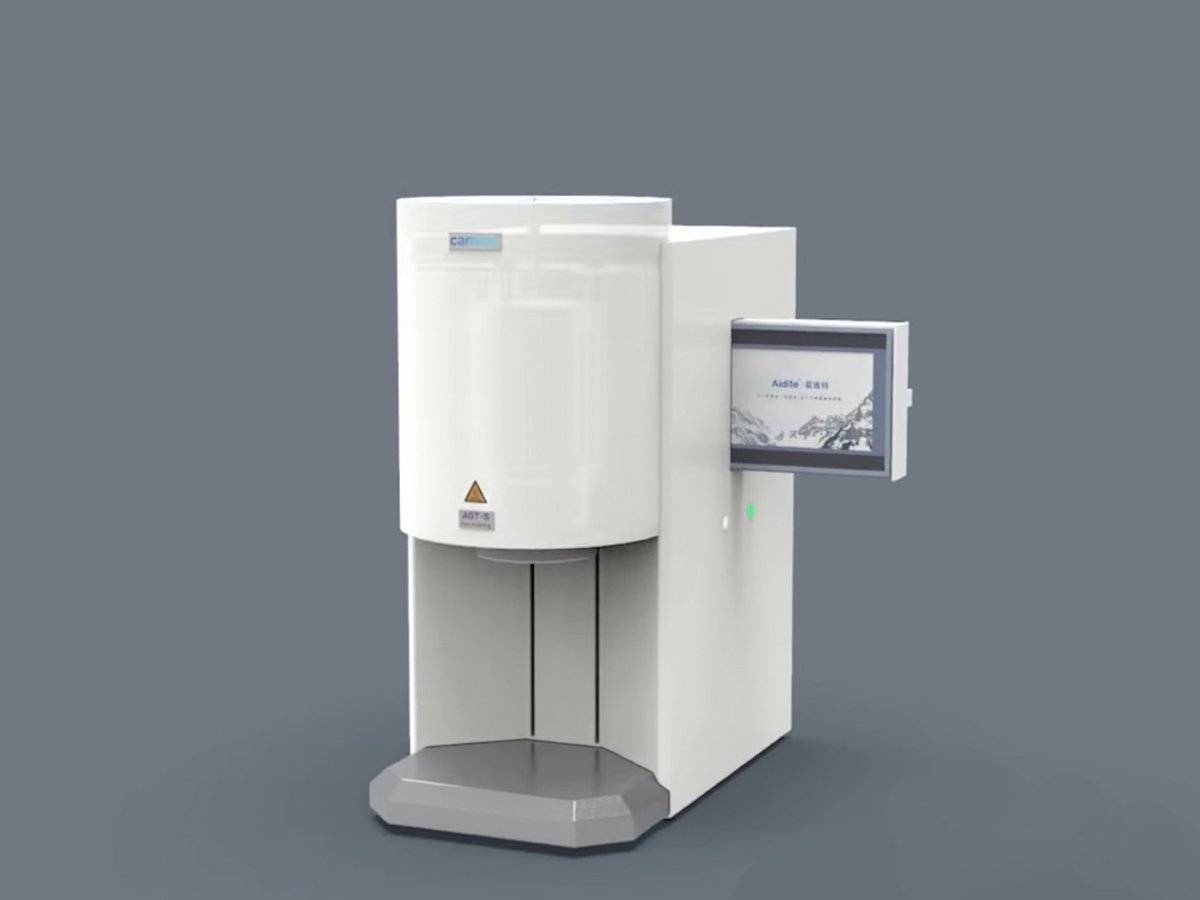

AGT-S dental furnace is a fast sintering furnace. This furnace has silicon carbon rods, which prevent the furnace from any pollution. It also has a remarkable energy-saving effect. It provides a user-friendly interface for easy operation. Its advanced technology provides accuracy of constant temperature to ±1℃. The remarkable feature is that the fast sintering does not have any adverse effects on the zirconia material.