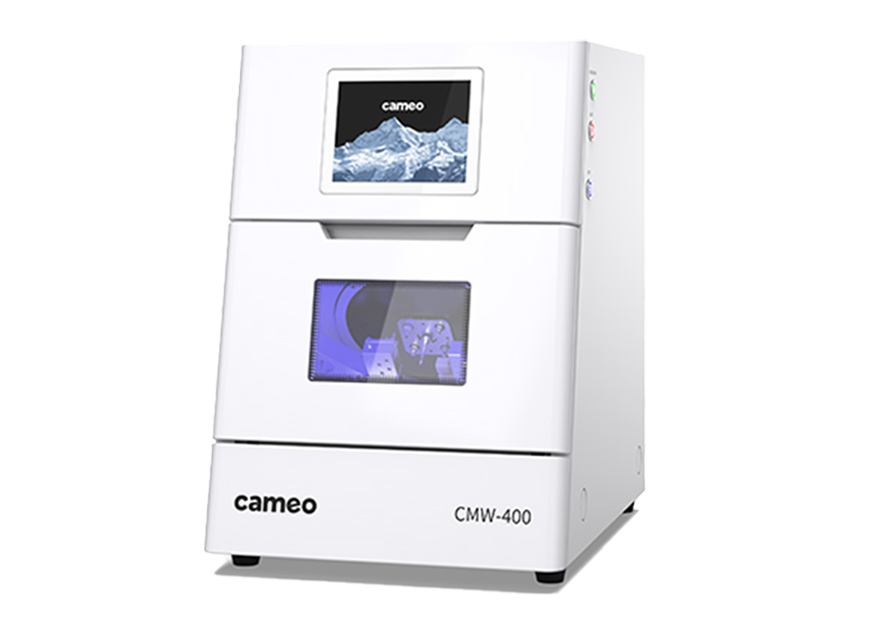

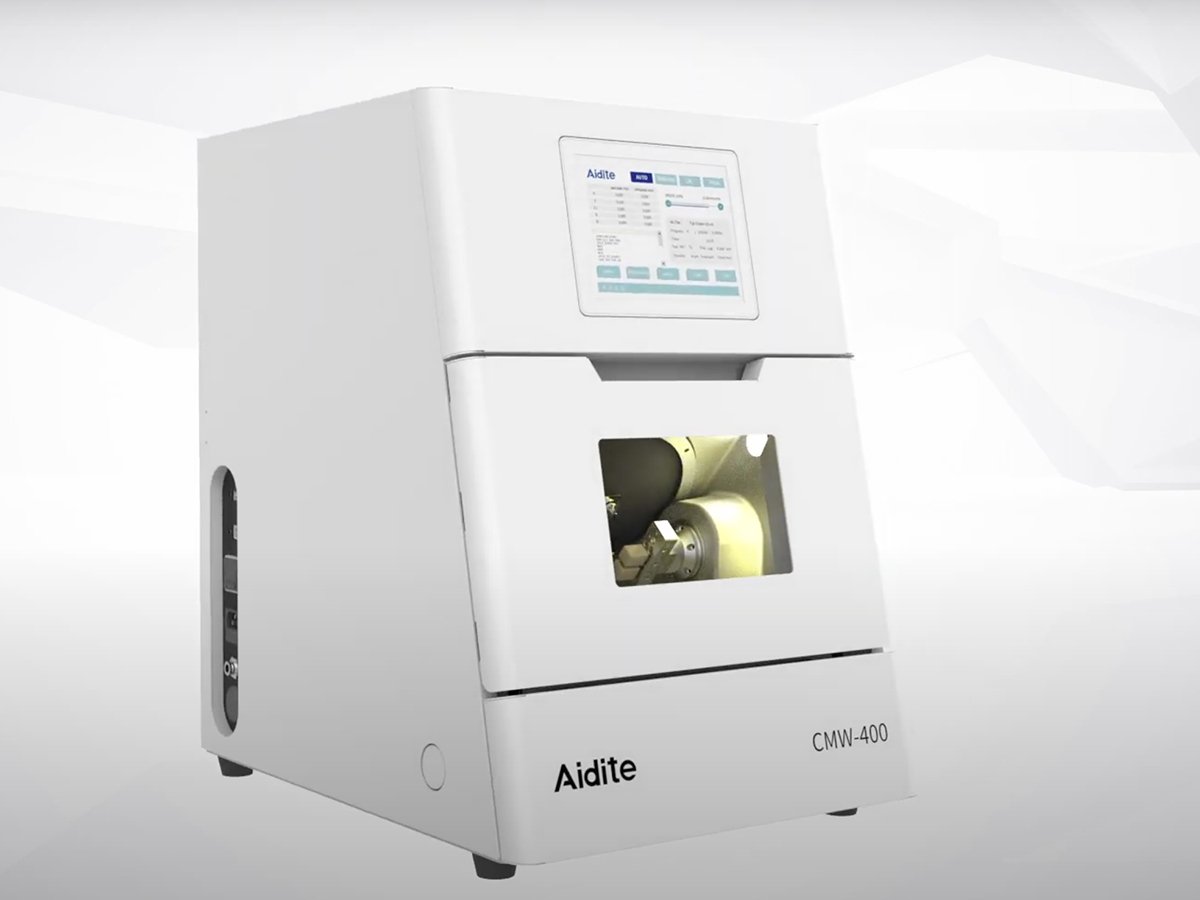

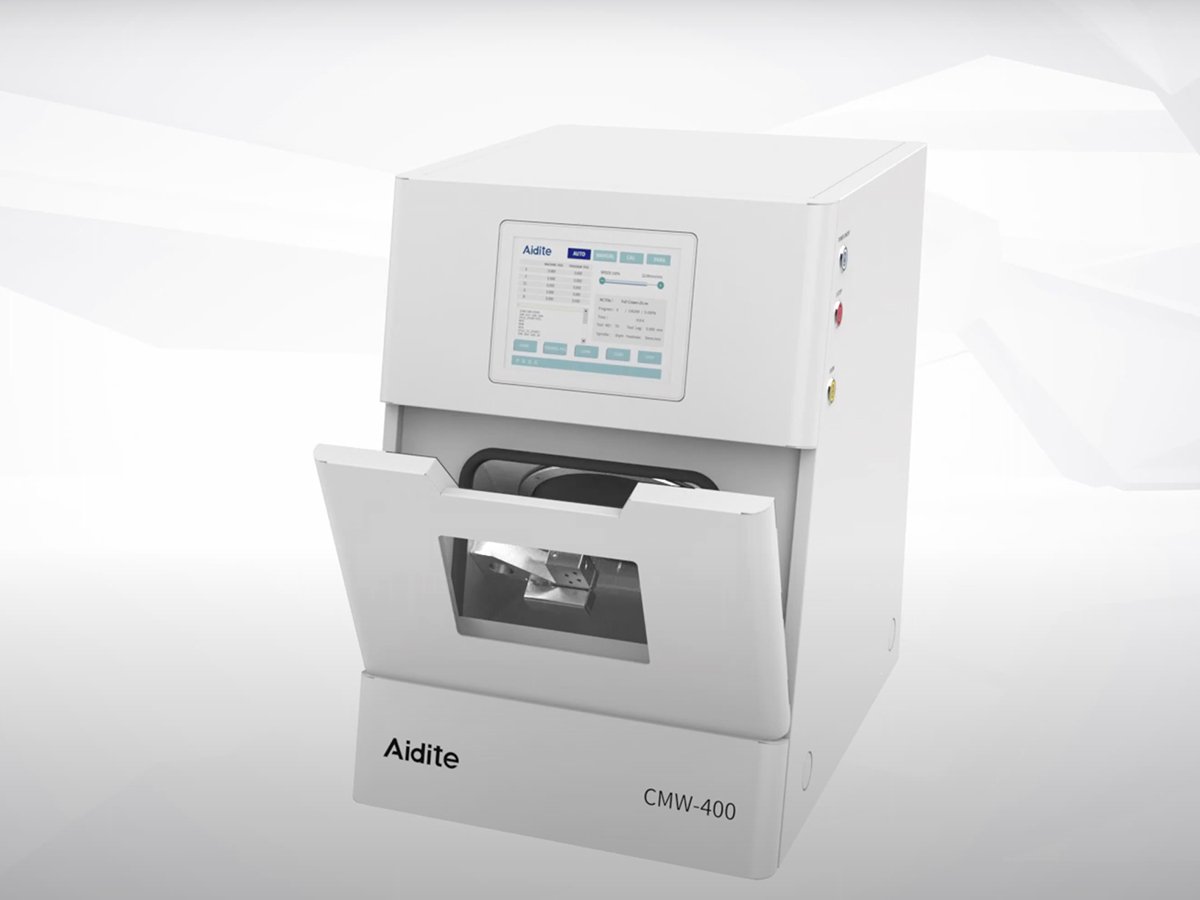

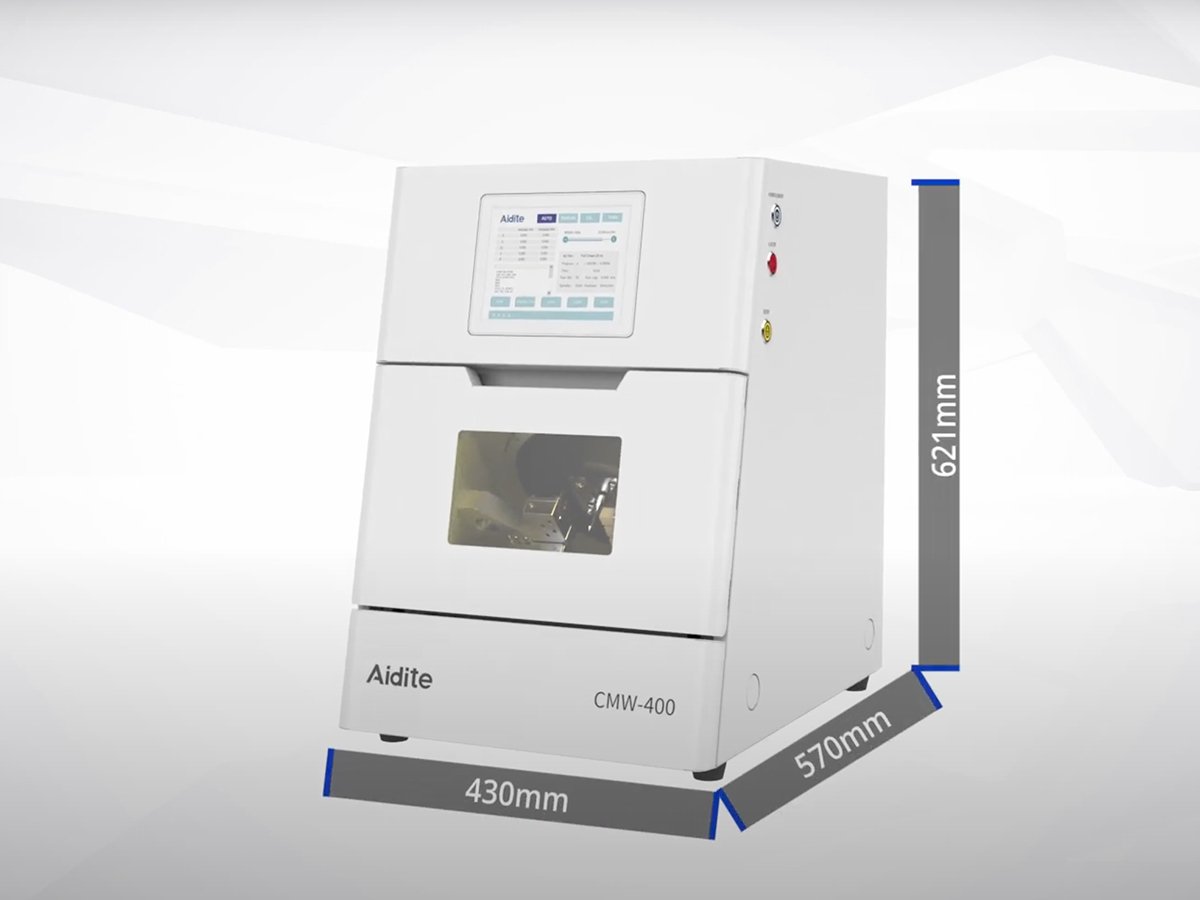

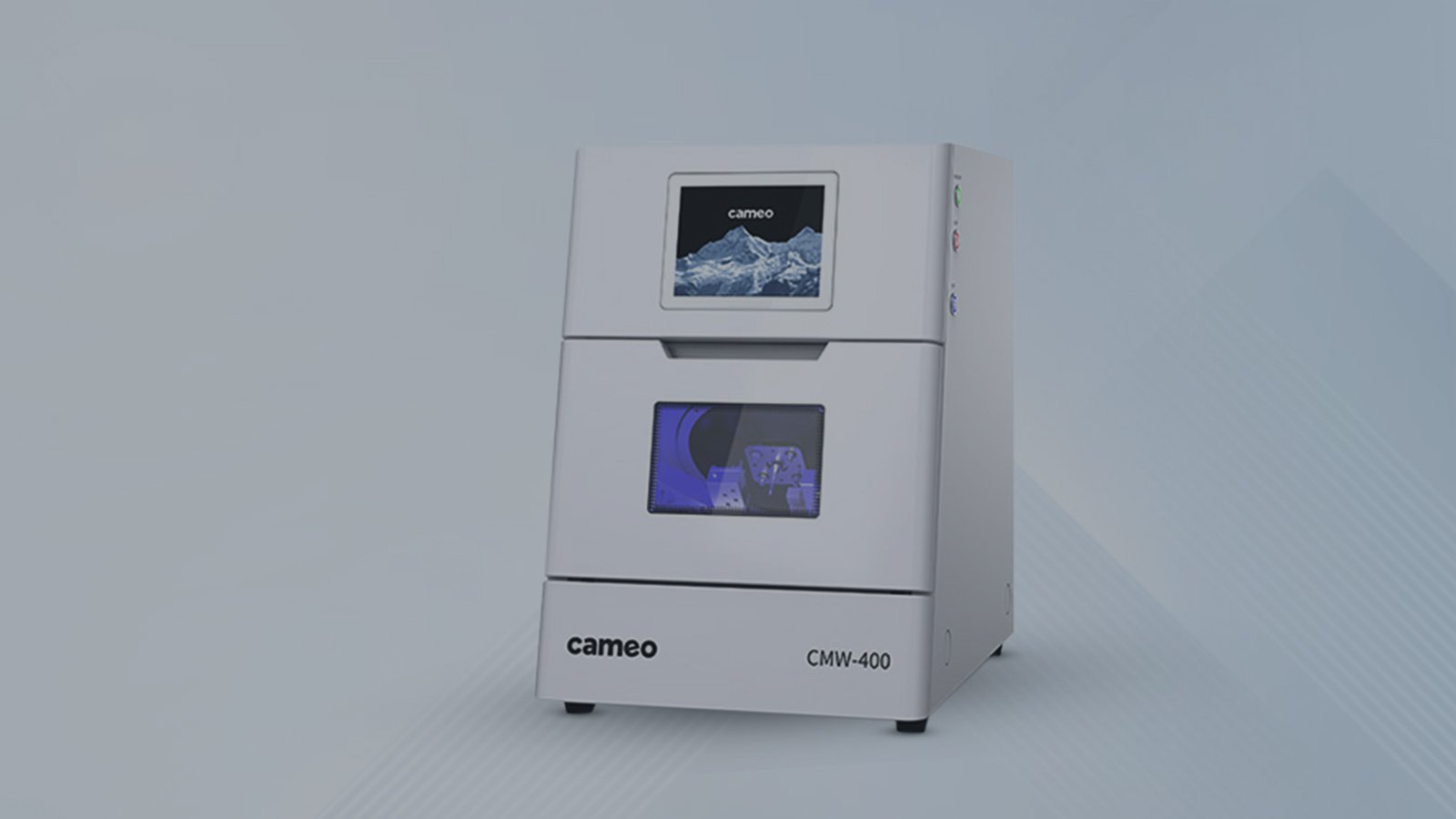

The CMW-400 Chairside Milling Machine is an innovative dental milling machine designed for dental clinics. It offers fast, precise wet milling of glass ceramics, premill abutments, and PMMA, ensuring efficient workflows and high-quality dental restorations. With features like tool life detection, an integrated water tank, and optimized CAD/CAM compatibility, the CMW-400 provides seamless restorations for dental professionals.